My mosaic fountain

loveapplefarm

19 years ago

Related Stories

GARDENING AND LANDSCAPING35 Fabulous Fountains

Cool Off and Be Soothed With a Little Water Music In Your Garden

Full Story

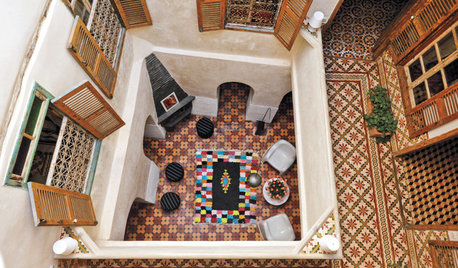

GARDENING AND LANDSCAPING10 Gorgeous Courtyards From Mod to Moroccan

Some have pools or fountains; some are awash only with greenery. These courtyards run the gamut of styles but have alluring looks in common

Full Story

LANDSCAPE DESIGN13 Extra-Cool Things to Do With a Backyard

Sure, you could just plop down on a blanket. Or you could create a dragon’s lair, a mosaic gallery, a party in a jungle ...

Full Story

COLOR8 Ways to Rev Up Your Garden Color With More Than Just Plants

Bring energy and excitement to your outdoor space by going bold with color, from small touches to big changes

Full Story

LANDSCAPE DESIGNUnwind in Your Own Private Garden Escape

When the world is getting on your last nerve, an outdoor refuge can soothe and nurture. Here's how to design a garden with relaxing in mind

Full Story

HOUZZ TOURSMy Houzz: Turning a Netherlands Barn Into a Country Home

Once a place for chilling milk, this Dutch home now lets the owners chill out in easygoing comfort

Full Story

LANDSCAPE DESIGNMake Your Garden Come Alive With a Sense of Movement

Master the illusion of motion for an exceptional garden that stirs emotions and the imagination

Full Story

GARDENING AND LANDSCAPINGPlan Your Patio at Summer's End? Yes!

Score fabulous deals for your deck, garden or patio and put your summer experience to good use in upgrading for the future

Full Story

LANDSCAPE DESIGNGet a Mediterranean-Style Garden Even Far From the Sea

Some lavender here, a water feature there, and your garden just might feel transported to a balmy seaside locale

Full Story

REMODELING GUIDESTile Floors Help a Hot Home Chill Out

Replace your hot-weather woes with a cool feel for toes when you treat your floors to deliciously refreshing tile

Full Story

eva1429

faltered

Related Professionals

Derry Landscape Architects & Landscape Designers · New Bedford Landscape Architects & Landscape Designers · Elwood Landscape Architects & Landscape Designers · Prairie Ridge Landscape Architects & Landscape Designers · West Chester Landscape Architects & Landscape Designers · Billerica Landscape Contractors · Wake Forest Landscape Contractors · Fort Mill Landscape Contractors · Metairie Landscape Contractors · Pahrump Landscape Contractors · Pine Hills Landscape Contractors · Weymouth Landscape Contractors · Whittier Landscape Contractors · Orange County Siding & Exteriors · South Windsor Siding & Exteriorseva1429

gardenrose

tomtuxman

Dena6355

Dena6355

iowajewel

butterbeanbaby

zooter

loveapplefarmOriginal Author

eva1429

suezn5

techsupport8

little_dani

loveapplefarmOriginal Author

klinger

Yasmine

Tnflower_lover

Janis_G