'Reverse' concrete form?

uvascanyon

12 years ago

Related Stories

DESIGN DICTIONARYBoard-Formed Concrete

Pouring concrete the old-school way leaves attractive wood-grain textural imprints

Full Story

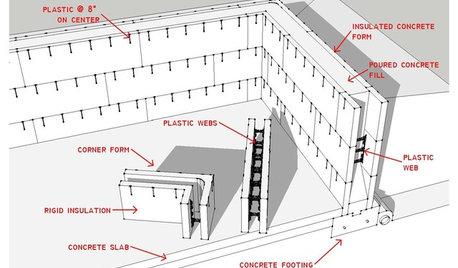

KNOW YOUR HOUSEKnow Your House: The Basics of Insulated Concrete Form Construction

Get peace and quiet inside and energy efficiency all around with this heavy-duty alternative to wood-frame construction

Full Story

DECORATING GUIDESMosaics Bring a Classical Art Form Home

Tile Art Adds Personal Style to a Backsplash, Bathroom, Fireplace or Patio

Full Story

REMODELING GUIDESModern Design Meets Traditional Forms

Contemporary Vernacular: Melding Today's Comforts With Indigenous Design

Full Story

ARCHITECTURERounded Forms Smooth Modern Architecture’s Edges

A simple curve or fluid line can soften and add interest to the look of your house, inside and out

Full Story

MODERN ARCHITECTURERoots of Style: International Style Celebrates Pure Form

Using technology and materials of the time, International style is always current. See its expression in these 16 homes around the world

Full Story

MODERN HOMESHouzz Tour: Complexity Hides Inside a Concrete Box

Don't be fooled by the monolithic exterior. This Canadian home is more open, light and multifaceted than it may seem

Full Story

FIREPLACESConcrete Panels Create a Stylish Modern Fireplace

A dozen distressed custom panels form a cohesive look without the mass that can sometimes lead to cracking

Full Story

REMODELING GUIDESLive the High Life With Upside-Down Floor Plans

A couple of Minnesota homes highlight the benefits of reverse floor plans

Full Story

DESIGN DICTIONARYPoured Concrete

No longer just for foundations, poured concrete is taking center stage in homes and gardens

Full Story

inkognito

tanowicki

Related Professionals

Essex Landscape Architects & Landscape Designers · Westwood Landscape Contractors · Annandale Landscape Contractors · Deerfield Beach Landscape Contractors · East Hanover Landscape Contractors · Haverhill Landscape Contractors · Paterson Landscape Contractors · San Carlos Park Landscape Contractors · Secaucus Landscape Contractors · The Woodlands Landscape Contractors · Palo Alto Decks, Patios & Outdoor Enclosures · Rantoul Decks, Patios & Outdoor Enclosures · Salt Lake City Decks, Patios & Outdoor Enclosures · Somerville Decks, Patios & Outdoor Enclosures · San Dimas Swimming Pool BuildersuvascanyonOriginal Author

inkognito

tanowicki

isabella__MA

missingtheobvious

deviant-deziner

marcinde

uvascanyonOriginal Author

missingtheobvious

uvascanyonOriginal Author

novascapes

deviant-deziner

adriennemb2

uvascanyonOriginal Author

novascapes

novascapes

uvascanyonOriginal Author

uvascanyonOriginal Author

novascapes

bahia

uvascanyonOriginal Author

novascapes

mjsee

uvascanyonOriginal Author

mjsee

novascapes

uvascanyonOriginal Author