Dremel tool

MAE060669

18 years ago

Related Stories

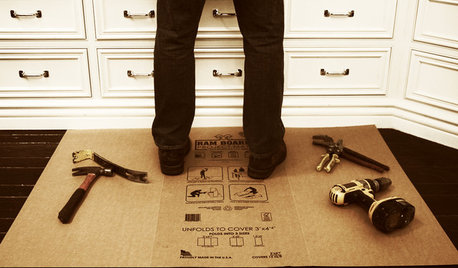

HOUSEKEEPING20 Tools Every Homeowner Should Have

You probably have a hammer, but that's just a start. These 20 tools and devices are superstars for household projects and repairs

Full Story

DIY PROJECTS14 Power Tools for the Home Shop

Want the thrill of building it yourself? These "big guns" help the handy homeowner tackle just about any job

Full Story

DIY PROJECTSMake a Marble Lamp Base With Tile

Get a lamp base that looks high end but costs only around $20, using basic tools and easy-to-find materials

Full Story

BATHROOM DESIGNOut With the Old Tile: 8 Steps to Prep for Demolition

This isn't a light DIY project: You'll need heavy-duty tools and plenty of protection for your home and yourself

Full Story

DIY PROJECTSHow to Replace Your Kitchen Faucet

Swap out an old faucet to give your kitchen a new look — it's a DIY project even a beginner can do

Full Story

MOST POPULARHouzzers Deck the Halls

From traditional to quirky to innovative, readers show their Christmas tree style

Full Story

MOST POPULARKitchen of the Week: Broken China Makes a Splash in This Kitchen

When life handed this homeowner a smashed plate, her designer delivered a one-of-a-kind wall covering to fit the cheerful new room

Full Story

BATHROOM DESIGN10 Top Tips for Getting Bathroom Tile Right

Good planning is essential for bathroom tile that's set properly and works with the rest of your renovation. These tips help you do it right

Full Story

MATERIALSWhat to Ask Before Choosing a Hardwood Floor

We give you the details on cost, installation, wood varieties and more to help you pick the right hardwood flooring

Full Story

LAUNDRY ROOMSSee an Amazing $400 Laundry Room Remodel for a Family of 8

Budget shopping and DIY spirit create folding space, smart storage and better organization for a couple and their 6 kids

Full StorySponsored

Belgianpup

rickharmer

Related Professionals

Allen Landscape Architects & Landscape Designers · Middle Island Landscape Architects & Landscape Designers · Lakeland Landscape Contractors · Peabody Landscape Contractors · Edmond Landscape Contractors · Surprise Landscape Contractors · Braintree Landscape Contractors · Federal Way Landscape Contractors · Goodlettsville Landscape Contractors · Indianapolis Landscape Contractors · Indio Landscape Contractors · Olympia Landscape Contractors · Pahrump Landscape Contractors · Streamwood Landscape Contractors · Chicago Ridge Landscape Contractorsairfun

tufaenough

airfun

rickharmer

tufaenough

susan6

Warren8

airfun

susan6