44 inch span styrofoam benchtop- under 15 lbs holds over 200 lbs

ltd123

18 years ago

Related Stories

KITCHEN STORAGEGoing Up: Vertical Storage Holds More Kitchen Stuff

Fit more of what you need at hand by looking to narrow or shallow kitchen spaces and walls

Full Story

GREAT HOME PROJECTSHow to Add Toe Kick Drawers for More Storage

Great project: Install low-lying drawers in your kitchen or bath to hold step stools, pet bowls, linens and more

Full Story

KITCHEN SINKSEverything You Need to Know About Farmhouse Sinks

They’re charming, homey, durable, elegant, functional and nostalgic. Those are just a few of the reasons they’re so popular

Full Story

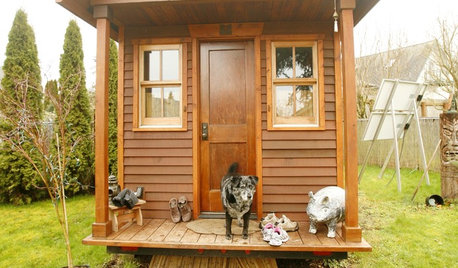

SMALL SPACESLife Lessons From 10 Years of Living in 84 Square Feet

Dee Williams was looking for a richer life. She found it by moving into a very tiny house

Full Story

KITCHEN DESIGNLove to Cook? We Want to See Your Kitchen

Houzz Call: Show us a photo of your great home kitchen and tell us how you’ve made it work for you

Full Story

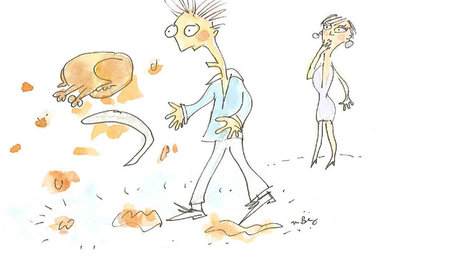

MOST POPULARThanksgiving Tales: When the Turkey Tanks

Houzz readers prove adept at snatching victory from the jaws of entertaining defeat

Full Story

KITCHEN STORAGEHow to Add a Pullout Spice Rack

Keep spices neat and free of kitchen grime by giving them a well-organized home in your cabinets

Full Story

GREEN BUILDINGThe Future of Smart Design: Reuse, Reduce, Recycle

See why reducing waste in a home construction project should appeal to every architect, designer and client

Full Story

DECKSDecking Materials Beyond Basic Lumber

Learn about softwoods, tropical hardwoods, composites and more for decks, including pros, cons and costs

Full Story

THE ART OF ARCHITECTUREDesign Workshop: The ‘Disappearing’ Guardrail

Putting the focus on the view instead of the rail on a porch or balcony is sometimes clearly the best option

Full StorySponsored

Central Ohio's Trusted Home Remodeler Specializing in Kitchens & Baths

klinger

Carolart

Related Professionals

Ferndale Landscape Architects & Landscape Designers · Graham Landscape Architects & Landscape Designers · Lakeland Landscape Contractors · Manchester Landscape Contractors · Surprise Landscape Contractors · Clayton Landscape Contractors · Dedham Landscape Contractors · El Segundo Landscape Contractors · Ellicott City Landscape Contractors · Eustis Landscape Contractors · Gurnee Landscape Contractors · San Carlos Park Landscape Contractors · Southbury Landscape Contractors · Thonotosassa Landscape Contractors · Vancouver Landscape Contractorsltd123Original Author

tufaenough

ltd123Original Author

tufaenough

ltd123Original Author

tufaenough

tango88

tufaenough

ltd123Original Author

rustinj

ltd123Original Author

kobold

ltd123Original Author

rustinj

Fleur

tufaenough

kobold

MuddyMesaWoman

klinger

rockhewer

DebZone8

wannadanc

ltd123Original Author

rickharmer

kobold

ltd123Original Author

rustinj

kobold

butterflybush

ltd123Original Author

Maxie1

tango88

kobold

rickharmer

tango88

ltd123Original Author

kobold

rustinj

nathanhurst

ltd123Original Author

Fleur

wannadanc

clairdo2

Mikey

Fleur

ltd123Original Author