Using Silicone Caulk as a Mold Material

I was reading the back posts and saw that some of you have been using silicone caulk for making molds. I have been working with a variety of silicones for some time and thought I'd post some information that might be helpful.

There are three basic types of silicone. The first two are two-part silicones which must be measured and mixed just prior to use.

1) Platinum cure (addition) silicones are extremely pure and can produce extremely accurate molds that last indefinately. They are used for medical and theatrical prosthetics, medical equipment, cookware, candy molds, and baby bottle nipples. Unfortunately, these are also the touchiest of the silicones to work with and their cure can be hindered by moisture, sulfur, latex, tin, loud cursing and bad hairstyles.

2) Tin cure (condensation) silicones are commonly used as a mold making material for art and industry. They are not approved for long term contact with the skin, or for cookware or other food contact, though some are used in making seals for potable water supplies. It is also long lasting and makes accurate molds with a life of several years. They are still very stable and safe compounds for a wide variety of applications. They will cure underwater and actually require some moisture in their chemical process. In fact, there is very little that will inhibit the cure of a condensation silicone.

3) The remaining class is one-part, self curing silicones like caulking and aquarium sealant. They are a variant of tin cure and are sold in air-tight tubes. These are further divided into two subclasses based on their catalyst:

a) Acetoxy - these are the typical ones you will find at your home centers etc. They have a strong vinegar (acetic acid) odor while curing.

b) Oxime - are referred to as odorless cure silicones and can be found in some building supply stores but are usually more expensive.

The biggest problems with using silicone caulking for molds is that it is rather thick and easily traps air, and that it will not cure properly in very thick applications. These can both be remedied in the same way.

The reason they won't cure in thick layers is that they require the moisture in air to cure. Thick layers develop an air-tight skin, effectively resealing the caulking underneath. In applications more than 1/4 inch thick, you can often come back days later and the underside will still be soft (if it is against a non-water bearing material like plasticine clay) or will cure from both sides and have a pocket of goo in the middle.

The way to solve this problem is to get some moisture throughout the silicone. You can't just mix in water, it won't mix well and you'll end up with a mess. The two products I have found that work best are glycerine (available at any pharmacy or in the health and beauty department of most chain stores) and acrylic (not oil) artists or craft paint.

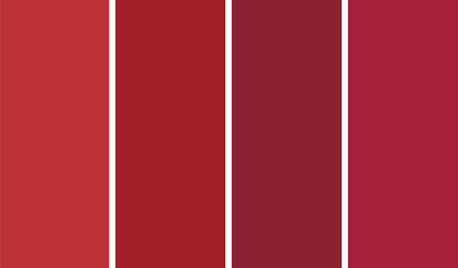

Start with clear 100% silicone caulk, like GE I or GE II, or DAP 100% Silicone Caulk. Squeeze out the amount you will need into a plastic cup that is large enough to give you stirring room. For each ounce of caulk, add four or five drops of glycerine and a drop of acrylic paint. Use a wooden craft stick to stir until you get a uniform color trying to avoid trapping any more air than necessary.

You can use just the acrylic paint, but I like adding the glycerine because it improves the cure and also reduces the adhesive qualities of the silicone, making it easier to remove from the model. You could also do this with just the glycerine, but it is more difficult to tell when you have obtained a uniform blend.

Don't overdo it with either the acrylic or the glycerine as more than a few drops per ounce will result in a weaker end product. You cannot thin caulking with these materials without sacrificing a lot of the good characteristics of the silicone.

Once you get a uniform color, you have from 15 minutes to an hour before the product begins to thicken, depending on the temperature and humidity. Working in a cool dry environment will extend your application window. If you are outdoors in southern Florida, in August, work fast.

Adequate cure for handling should take under two hours and it will cure evenly throughout, rather than from the surface inward. Again, heat and humidity will speed things up.

I like to brush on a thin layer first, getting out all the air bubbles and making sure you have good contact everywhere. Then a thicker coat can be spatulated on. Usually about 1/4 inch works for palm sized items, but you can go up to an inch for very large works.

Once the silicone has cured, you can make a support shell out of plaster bandages applied a couple of layers thick. This "mother" mold will hold the flexible silicone in place during casting. Again, the bigger the mold, the thicker the mother.

Though it is probably not necessary, I like to give my newly made molds overnight to finish curing before I start casting in them.

If you feel you need to thin silicone caulking, xylene is the solvent of choice, but work outdoors and protect yourself from the vapors, they can cause health problems, so read the label. Mineral spirits will also work, but weaken the material and leave it with a greasy feel. Mineral spirits will also slow the cure from hours to possibly days.

Also, volatile solvents will result in shrinkage of the finished mold in proportion to the amount of solvent added to the silicone.

I personally like dry mold releases rather than greasy ones. For porous materials like plaster, I like to buff in several coats of Johnson's paste wax, leaving only a micro thin layer on the surface and then allowing it to completely haze over before making the mold.

For non-pourous surfaces, like glass, I take Ivory dish soap and mix it 1:3 with distilled water. Use a soft artist's brush and swish the sudsy mix over the surface of the model while drying with a blow drier in the other hand. The result should be a thin soap film that is relatively dry to the touch.

Petroleum jelly (Vasoline) will also work, but is messy to clean up. I don't like PAM or other cooking sprays.

Silicone sprays make great mold releases for everything EXCEPT silicone. They tend to become part of the mold and may actually increase adhesion.

Also avoid petroleum based lubricating sprays. They are messy and make it difficult to brush the silicone over the surface evenly.

For really difficult releases, there is a material called PVA (polyvinyl alcohol) sold in craft stores that sell acrylic casting kits used for making clear paperweights and such. Brush it on, let it dry, and then apply a thin film of paste wax. If that won't release it, nothing will.

PVA is soluable in water, so don't try to use the soap film for the secondary release.

When making a cast in a silicone mold, a release often isn't necessary as not much sticks to silicone, except more silicone. If you feel you must use a release anyway, silicone spray lube, soap, paste wax, or PVA will all work.

Comments (72)

Old_hippy

18 years agolast modified: 9 years agoThank you Nofu for the great info. I've been wanting to try my hand at silicone molds for years ('cause I'd like to try selling some of my stuff) but have never found any free info like this. You just made my day.

packrat2

18 years agolast modified: 9 years agoYup, it's nice to see this great info pop up again and I'm going to print it now, even though I'm not thinking about making molds at the moment .... can't count on things like this not dropping off since the "bumping" was cut.

Thanks Nofu.

packrat2Related Professionals

New Bedford Landscape Architects & Landscape Designers · Prairie Ridge Landscape Architects & Landscape Designers · Tomball Landscape Architects & Landscape Designers · Allentown Landscape Contractors · Fairfield Landscape Contractors · Galt Landscape Contractors · Lemoore Landscape Contractors · Mason Landscape Contractors · Mount Kisco Landscape Contractors · Nashua Landscape Contractors · Newberg Landscape Contractors · Point Pleasant Landscape Contractors · Round Lake Landscape Contractors · West Palm Beach Landscape Contractors · Camp Springs Landscape Contractorsslate1

18 years agolast modified: 9 years agoHi Nofu,

thanks for the concise and readable info on silicone molds.

A question for ya though. You mentioned that you have done slush casting with latex molds, if I understand correctly.

I have a latex mold of a statue, about 2ft high, 8" wide and deep. It sits in a fiberglass mother- mold, and as you would appreciate, the cast is real heavy. I'm still searching for a way to reduce the weight of the cast some more, and I've tried slush casting, as in hand layup, with a thick sand/cem mix, but it collapses back into the 'bottom' of the mold ( which is actually the top of the cast).

Could you give me any information on how to go about this?

With help from others on the forum, I used a 'plug' inserted into the body of the pour, at the time of pouring the cast, but I still want to reduce the weight of the piece some more, and any info would be much appreciated,

Thanks again, esp. for the treatment of the silicone application,

Slaterickharmer

18 years agolast modified: 9 years agoOK-got silicone,got glycerine,got paint-check,check and check.

So,you say use a few drops of glycerine per OUNCE of silicone.What kind of ounce.Liquid or by weight?

got the Molding and Casting handbook by Thurston James.He says silicone will stick to just about everything.Does the glycerine stop this?Thanks,your instructive narrative helps me a lot for the smaller molds.

cheers from hererockhewer

18 years agolast modified: 9 years agoRick, You have to use a release to make a silicone mold too. On plaster models some people use Murphys oil soap as a release. Not too much or the silicone will slide off. I used petroleum jelly dissolved in a solvent on my plaster models. It allows for a thin film of PJ to be on the surface after the solvent dissapates.Your model has to be resistant to any solvent used though. The PJ than can be cleaned off the finished silicone mold so nothing will transfer to the finished cast.

EasterIslandGiant

18 years agolast modified: 9 years agoI use a liquid plastic rubber called evergreen and also flo-flex or vita-flex.

the product take 16 hours to set but gives a mold that is stiff and flexible. this product cost 45$ for a 1/4 brick size sample.

the vita-flex works great for lots of mold and you need to spray the Mold Release Agents on the form.

these products come with two liquid that you mix and stir slowly then pour gently and thats it.

the Mold Release Agents is what I sugest you try. this works good with the product i use and liquid plastic stick to anything alot... the release agent really works..

Here is a link that might be useful: smooth-on website

rickharmer

18 years agolast modified: 9 years agoWell,as a brand new moldmaker,I found this thread valuable as all get out!Mixed the stuff up,applied it to a clay piece(coated in Pet jelly,diluted)and shazam!!popped the mold off this a.m.,all's well.Thanks to your detailed info.You are one knowledgeable "Cretehead".If you could only do my taxes,why,you'd be perfect!!

Cheers from hererockhewer

18 years agolast modified: 9 years agoCongratulations there Rick, Theres nothing like a success to start the day off !! I found this thread to be the best also in helping me too. WTG

buckyforce

18 years agolast modified: 9 years agoHey Nofu!

Way to go, and thanks! Between your recipe using Silicone caulk (GE1, glycerine and acrylic) AND the advice of Tango regarding release agents for my gritty master, I think Shazam, as Rickharmer so eloquently put it,is it! Tomorrow I demold and have high hopes!!

I bit the bullet last year and spent a bunch o' money for the 2-part Polytek latex. Made 2 molds, a few months apart, quite successfully and stored the supplies. Imagine my surprise when I went to use it again this weekend and it was d-e-a-d! Part A was as hard as Chinese arithmetic and Part B looked like, well, you don't want to know. I then found some high quality silicone in my tool box and before checking here first, loaded up the caulking gun and covered my carefully prepared master. Ater 24 hours it was still as sticky and gooey as when it was applied. Imagine my surprise when I took a look at the tube and it had expired in 6/04! Scoop, curse my impatience, scrub with solvent, reapply wax release. Off to HD to get GE silicone. A little warning for all of you shopping at HD, or anywhere else for that matter. LOOK AT THE EXPIRATION DATES! The tube I used out of my toolbox was my own fault, but today I found two tubes at HD with expiration dates of '03 mixed in with the "new" silicone! I also think it is a good idea to search for tubes with the same batch numbers/use by dates if you plan on using more than one tube on the same project.

Can't wait to demold and can't thank all of you for your wonderful advice!

(Anyone want to buy some lion's paw planter feet?)

Amanda

rockhewer

18 years agolast modified: 9 years agoBuckyforce, Did you mix the silicone with anything? I just used two tubes of silicone that had expired in 4/04 with no problem. The tubes had been kept in a basement with fairly even temps though. I dont know if that has anything to do with it. You are right on about looking for expiration dates on everything you buy. That can save many headaches.

buckyforce

18 years agolast modified: 9 years agoHi Rockhewer,

For the second, successful batch I used the GE1 silicone, glycerine & Acrylic as specified in this post. The first mess I added nothing. Straight out of the tube. All the mess I scraped off STILL hasn't even begun to set up and it has been 3 days. I'm in So. Fla. so the heat could have affected the unopened tube. Who knows.

De-molded the "good" stuff this morning. Yippee!! Perfect! Plan on casting tonight - can't wait!

Will post a pic of the cast copy along side the master when it is demolded if anyone is interested.

Thanks all!

Amanda

spclfxguy

18 years agolast modified: 9 years agoNofu: Your silicone info reads like that of an experienced mold maker in the FX Industry! :-)

If I may, I'd like to add a few notes that relate to some of the types of products you suggested, as well as some feedback to a few techniques being attempted by members, herein...

First of all, one of the most widely used, reliable, virtually idiot-proof silicone products used today in the FX industry is GI-1000, Sold by Silicones Inc. They will ship the product to you, and also have distributors all over the USA, which might save you $$ if there is a distributor close to you.

Their web address is http://www.silicones-inc.com/home.htm

GI-1000 is an extremely high tear strength, tin-catalyzed RTV-2 (meaning 2-part) silicone rubber, which was designed for casting polyester (resin used in casting fiberglass) parts.

GI-1000 is not sensitive to inhibition, meaning it will cure at room temperature over virtually any surface. It is easy to mix and de-air, and will cure with only a slight degree of shrinkage.

The speed at which the rubber hardens can be accelerated with special activators. Condensation cure two-component silicone rubbers are excellent for most general mold making and prototype applications. They are excellent for casting waxes, gypsum, epoxies and other plastics.

If you need to do a brush-up mold, and require a less "runny" Silicone product, there is hope! It's called THIXOTROPIC Silicone, and can be brushed up** and doesn't run everywhere...

(Now that I think about it, I can't recall if Silicones Inc. carries this, or not - if not, a place called Silpak, Inc. - located on Burbank Blvd., in Burbank or North Hollywood, CA - should, but they carry their own silicone product(s) - just ask for the TIN based, THIXOTROPIC Silicone)

NOTE: This is kind of a "hack" method we use for producing a quick & dirty "1-off" mold, which is actually good for more than one casting, and will last indefinitely, depending on how well/durable you make your mold and what you are casting in it...

**You guys will love this:

Have you ever just wished there was a better way to apply silicone than using a brush or the caulking gun? When you are ready to apply a thin layer/coat of silicone onto something, go to your kitchen, grab a couple paper towels, open the freezer, grab a couple ice cubes, wrap one of them with a paper towel (or two - this is used to keep your fingertips from freezing off), leaving about 1/3 of the cube exposed. Squirt/pour/brush a blob of Silicone onto your part, now take your ice cube and use it to manipulate the silicone all around your part. You will be amazed at how cooperative it will be! You can control the overall thickness without the stringy mess that using a brush often creates and, since it is water, it will not inhibit the cure of your silicone!Once you have brushed up a layer or two of silicone, you can gently tamp in some cheesecloth, to add a bit of durability to it. After you get it built up to a decent thickness, you can then apply whatever kind of support you feel will last for as long as you think you will need to use your mold - plaster bandage, solid plaster, fiberglass, etc.

Someone asked about slush-casting - needing a lightweight material...

My first suggestion would be to consider adding some Vermiculite (any decent plaster/stone distributor will know what this is) to your casting, to lighten it up (it may compromise the strength/durability, so take that into consideration!)

You can also try adding some Acryl 80 acrylic adhesive to your plaster/stone mix. If your mold is made in 2 or more pieces, use a disposable brush to apply a slip coat layer into the open faced halves, brushing the stone to the very edges.

Once this cures out, mix up another batch of stone w/Acryl 80 and generously brush it onto the flanges, then join the mold together. Let that set up, then either back-fill the mold w/solid stone w/Acryl 80 or, what I have sometimes done, backfill the part with polyurethane foam, leaving enough room to finish it off with a small batch of stone/Acryl 80 mix, to seal everything in and give the impression it is solid, without the weight.

There is a gypsum cement that can have glass fiber applied to it, in practically the same manner as you would with polyester resin! I can't recall the exact name of the stone, but BURMAN INDUSTRIES (google it - I don't have it handy) might be able to tell you what it is - Anyway, this is widely used in the decorative sculpture industry, in columns, fireplaces, etc. I've used it to make Mother Molds as well as for casting! It's worth looking it up!

I hope some of this information is helpful to someone... Sorry it doesn't have as nice a "flow" as Nofu's does, when reading it.

Audacitie

18 years agolast modified: 9 years agoSilicone caulk is runny? I bought 4 tubes to try to make a mold of a tray with a relief pattern on it. I had a lot of trouble trying to spread it out, even with ice cubes. I wish it had been runny, it then would have flowed over the surface instead of having to push it around. And brush it on? Forget about it, at least the 100% silicone that I used. When I demolded I had lots of air pockets as well. So I bought yet another tube to try to fill those in, have not yet done it. I think I'm at about $18 into caulk. sigh...My husband, who was drafted into the role of assistant, didn't think it much fun either.

Aud

tufaenough

18 years agolast modified: 9 years agoHave you considered wax?

If you have no undercuts wax is great if you just want a cast or two.

I cast concrete fonts in a block of wax, and other small stuff as well.

I plan to spend more time with wax this winter.

I use body wax because of the very low melting point.

Great thing is you can use it over and over.

Add sand or pea gravel and you get great texture.

I do brick faces that look like rock by dripping wax on my workbench to get that layered sandstone look.

. .mudwitch

18 years agolast modified: 9 years agoOh, My !! This is a lot of info. I will be looking at this for some time. Thank you for the information.

Kayleeno1

18 years agolast modified: 9 years agoI just found this site today and was excited to read about a way to be able to make the silicone caulk molds thicker if needed, and still get a good cure. Thanks so much! I would like to share with you way I apply the caulk to the model and avoid a big, gooey mess. I keep my gloved hands wet with a solution of dish soap and warm water. Just keep a little bowl with a few tablespoons of soap (I've found almost any brand will do) and warm water and frequently dip my fingers in it. I squeeze a bit of the caulk directly on the release-covered model, dip my fingers in the soapy water, and pat the caulk 1/4 " thick. The artist who taught this method had us squeeze the blob of caulk into the soapy water, pick it up, place it on the model, and pat it out but I find my shortcut works just fine. Also, I tend to prefer the clear caulk so I can see if I'm leaving voids.

Running_Dog

18 years agolast modified: 9 years agoAudacitie - the only way I know to control silicone is to squeeze the whole tube into a basin of warm water with detergent in it. Then you scoop the whole lot out, plonk it onto whatever you're taking the mould from, and press it down onto it. It will be very soft, you can flatten it out well. Keep dipping your hands back into the basin of soapy water to prevent the silicone sticking to them.

computer_dork

17 years agolast modified: 9 years agookay, so I used the recipe above (thanks so much for posting it!) and it was a bit too sticky. I'm using it on a concrete piece that I am making a mold of and I could not get an even coat because it kept sticking to my fingers.

So, my question is this - how thin can I thin out the silicone with mineral spirits before it doesn't hold up as a mold?

Is is possible to thin it out with something to a pourable consistency?

Thanks in advance for all of the input!

jim_i

16 years agolast modified: 9 years agoCan you use silicome caolk molds for pouring melted pewter?

tehuti

16 years agolast modified: 9 years agoThanks for posting this information. I mixed some silicone with glycerine and RIT yellow liquid dye (fabric) as a test. I had some clear glass button I wanted to use as eyes on a dragonfly but plain silicone didn't give me any depth. Here is a picture of the eye portion of the unfinished dragonfly.

{{gwi:75713}}Thanks,

Roberttehuti

16 years agolast modified: 9 years agoThanks for posting this information. I mixed some silicone with glycerine and RIT yellow liquid dye (fabric) as a test. I had some clear glass button I wanted to use as eyes on a dragonfly but plain silicone didn't give me any depth. Here is a picture of the eye portion of the unfinished dragonfly.

{{gwi:75713}}Thanks,

Robertgardener104

15 years agolast modified: 9 years agoI was really excited when I read the original post and I've been trying silicone mixed with glycerine to make molds from manhole covers. It's a particularly difficult project because of the public nature of it. I really need the mold to set up quickly, but I'm finding it takes many hours or even overnight.

What am I doing wrong? Too much glycerine or not enough?

I didn't pay attention to the color but I just had one where I mixed 2 batches, and the one that was clear set up much better than the one that was white. Is this my imagination?marcia7439

15 years agolast modified: 9 years agoThinner layers....if the silicone is too thick, it will take forever to completely cure...

I also make my molds with just silicone. I squeeze the tube into a container of very warm water with dish soap, and gently take the silicone and place it over my master. Try it on something small first.

Marciadaisy_ny6

15 years agolast modified: 9 years agoI don't think it's suitable for something both large & quick. You might be better off using alginate & then quickly casting with plaster, take it home & make a permanent mold.

marcia7439

15 years agolast modified: 9 years agowould it be possible for you to visit your Department of public works and borrow one of their manhole covers? Take it home and then return it? I am sure they would have what you want in their 'yard'. Maybe offer them a security deposit of some sort......

Just a thought.

Marcianmgirl

15 years agolast modified: 9 years agoI think my brain just exploded from all this knowledge!

I see new projects stretching out, on and on, vanishing into the horizon.

I also see my husband's wish to use the garage for parking cars vanishing into the horizon too.jpjr

15 years agolast modified: 9 years agoCan you use this method for casting white metal? (WM melts around 230 deg.) and since Silicone is resitant up to 500 deg. it should work... right? RIGHT?????!?

svoboda

15 years agolast modified: 9 years agoLots of great info here. I hope I can return the favor.

I experimented with glycerin and paint for curing GE Silicone 1. The glycerin may reduce adhesion, but it didn't seem to help the silicone cure. The paint was effective.

My magic ingredient for curing GE Silicone 1 is bleach; liquid laundry bleach. I use 2 drops per full trigger squeese of my caulking gun. This is a ratio of 90 parts silicon to 1 part bleach. This works out to a little less than 3/4 tsp per 10.1oz tube of caulking. The pot life is short and the cure is quick. I can de-mold in 30 to 45 minutes when the ambient temperature is in the 60s. I expect this will work well for the man hole cover problem.

aartwmich

15 years agolast modified: 9 years agoIts great that all this info is still here from way back in 2004Âit got me started when I was attempting to make some molds this last fall for my concrete leaves.

I will now add my experiences to possibly help others now and in the future.I tried using the 100% silicone caulk and glycerin method outlined by Nofu above(I learned A LOT from that great info Nofu, thanks!), but I found it to be tough to mix and get the mixture right to keep pot life reasonable. First batch was great, second batch was bad. Plus the volume I needed to make a mold for a 18" x 12" rhubarb leaf made the thought of mixing the glycerin with the silicone in that size batch rather intimidating and difficult.

So I tried the caulk straight out of the tube using a caulk gun to make molds for my concrete leaves. It worked great!..on the first 2..... which hadn't been fully scrubbed and rinsed and thus had some 'dust' on them..... the 3rd one had been cleaned well and the silicone did NOT come off :(

So I did some research and thinking and talking to buddies and did some testing for a mold relase. I tried olive oil, mineral oil, vegetable oil and paste wax. The paste wax was by far the best method. This is good ole Johnsons paste wax from a can I had laying around that my dad bought probably 40 years ago. I apply the paste wax to the leaf with a short stiff (1/2" x 1/2") paint brush making sure to get it into all the nooks and crannies. I sometimes used a hair dryer set on 'hot' to warm the concrete leaf and the wax so it would spread better.

I then apply the silicone caulk using the caulk gun to layout the needed amount onto the leaf and to force it down into the deep veins then use one or two fingers dipped into soapy water(flicking the excess liquid off) to smooth it out and produce the proper thickness. I do a smallish section at a time and keep the edges of the section 'wet' so as not to form any lines upon the surface of the leaf mold.

The clear silicone is best because you can see any bubbles that might get trapped against the surface of the concrete leaf. I use a layer no more than 1/8" to 1/4" thick so it will fully cure, any thicker and it will not cure. I found that you can use another layer to thicken up larger mold and also to repair any tears that might happen down the road.

VERY IMPORTANT NOTE: Use a carbon cartridge respirator or the fumes will knock you out(after you vomit). NOT a paper particulate mask, but a real carbon cartridge mask, you can get them at HD for about 30 bucks.

The mold must be peeled off the master concrete leaf very carefully, some areas need to be picked out with a dental tool or something similar. Same goes with taking the mold off of the newly cast leaf. Some areas of the mold that were too difficult to remove from the cast leaf I have trimmed off so they wonÂt get stuck on the next castings or tear the mold. Again, a torn mold might be able to be repiared wit some more silicone

I then also made mold mothers out of plaster to hold the molds in the original shape of the 'master' concrete leaf while casting the replica leaf. I have just tried using wet mounded sand as a mold mother to create a different shape to the molded leaf, it worked well.

I made 14 different concrete leaves using mortar mix (1:2 cement:sand) from Rhubarb to Maple over this last summer. Once the leaves started dying in the fall I realized that making the molds would be a good idea to be able to use thru the winter. It worked out well and now I can cast a large leaf in about an hour. I turn out the leaves from the molds after 24 hours, so the concrete is still 'green'(soft enough) and take another hour to trim off any overflows or warts using a wood rasp. I then soak the concrete leaf totally submerged in water for a week to fully cure the concrete. A buddy of mine who is an expert in concrete (he works for the Deparatment of Transprotation-the guys who build our highways) told me that complete submersion is the best way for concrete to fully cure. I then apply an acrylic paint wash to color the leaves.

I keep my Âmaster concrete leaves made with the Âreal leaf on a pile of sand method in case I ever need to make another mold, tho the molds seem to hold up rather well.

sherida_2009

15 years agolast modified: 9 years agoAll this info is just wonderful. I made a leaf mold from the liquid latex last fall and it works good but takes so long for all the coats. Cannot wait to try the silicone method. Keep the info coming all !

mikeflo

14 years agolast modified: 9 years agoHello, I decided to pick up mold making as a hobby so im new at this. I have a couple of questions: 1) I would like to make a clear soft silicone gel mold enough to withstand a variety of weight. 2) I would like to adhere materials such as cotton, neoprene or perhaps nylon to the silicone. Any suggestions out there if I have to special order thru online or find the silicone locally? Thank You

billie_ann

14 years agolast modified: 9 years agoTake a look at Smooth-On's web site. They sell a lot of different supplies for making molds, lifecastings, etc. Go to the "How to" section for mold making information. Billie

mutelf

13 years agolast modified: 9 years agoI just discovered all this wonderful info & was wondering if the silicone caulk (with glycerine & acrylic paint added) would be suitable for making a mold of a vinyl ceiling tile that I found at a yard sale? The tile is 2' x 2' and is the type that emulates the old pressed-tin or metal ceilings. It's not very thick with a bit of detail - kind of a Victorian type design and I am cautious about using anything that will produce heat which might destroy my 'master'. (Just in case I need to make more molds.) In theory since the back of the tile is inset about 1" and the top design is reversed on the interior, I could possibly cast directly into the original tile. However, since I'm planning on using plaster of paris to cast, wouldn't there still be a heat issue to consider? If I remember correctly POP heats up while curing...which of course, again, would ruin my master. Any thoughts? Assuming of course that anyone is still reading this? Thanks!

jolj

13 years agolast modified: 9 years agoIf I make a mold from river rock, will the hypertufa be strong enough to stack. I would like to stack two high & two deep. Should I use cement with a powdered color instead?

warart

12 years agolast modified: 9 years agoI used Vaseline as a release agent on a gold leafed plaster frame I was trying to restore and the Silicone Caulk bonded to the frame making it nearly impossible for me to get the dried Silicone off. I had to pick pieces off (for hours) until I could get no more, then I used several powerful solvents and finally got the remaining bits off. I rubbed the area I was working on so much that it removed some definition in that area though. I'm going to try paste wax next and I'm going to try it on a place on the frame that wont matter much first.

ban-ma

11 years agolast modified: 9 years agoso happy i ran across this post, with that said i have a question i saw a post where someone asked if layers of silicone may be applied one after the other before the first layer is cured, if i read all the info correct silicone will stick to silicone so if it is cured between each layer it should stick and then if it isn't it should stick but may not cure all the way though? anyway i was sure there was enough trying this out that by now someone should be able to help.

thanks

ban-ma from missourifa_siddhartha

10 years agolast modified: 9 years agoHi dear friends!

I've read about liquid silicone rubber, & I know it needs heat to be cured,& without enough heat it takes a long time for it to be cured. But I need to make molds in my room with LSR silicone. I wanted you to please help me know how can I make molds with lsr in an oven?

Thank you so much,

Siddharthacntryboy

10 years agolast modified: 9 years agoThanks for all the information guys and gals. The mix ratio nofu was talking about acrylic and glycerin and silicone does it come out rubbery? Im wanting to do a couple old figurines and want it to come out as close to skin as possible. If anyone has any info please let me know thx.

abuhafss

7 years agoI was looking to screen some patterns with silicone on different surfaces like hardboard, MDF, carboard etc. For that I diluted Silicone caulk with Xylene and added some normal oil paint. I was able to get positive result except that the dilution weakened the adhesion property of the silicone which ultimately failed the whole experiment.

The screened layer was about 1mm thick. The cured layer was easily removable by gentle rubbing with finger or thumb.

I shall appreciate if anyone could help me sort out this problem.

Hristofor Cherkezov

7 years agolast modified: 7 years agoGreetings!

I've been browsing the net for tips on just this subject and your thread has answered a lot of questions - thank you! I just have one more inquiry - do you know of a way to make the end product of one-part self curing silicones (after curing) softer and stretchier (lets say more like human skin, goal hardness is 10-30 shore A)? The reason I'm asking: I am a resident in heart surgery and I'm trying to make practice models of parts of the human heart and tissue to use for training outside the operating room. As you said the platinum cure silicones are used for this purpose but the price difference is tenfold and they're a bit too expensive for us.

Terrah Day

6 years agoI too have learned from this thread! I hope to try, just making a small mold first with the tube of Silicone.

Am wondering how long a tube of Silicone would be good after opening?

HU-71463457

5 years agoI have already made my mold with the silicone II plus cornstarch, there was glycerine involved as well. I’m having a hard time getting it to cure since I realize I made it too thick. It is molded around a 4” X 4” pyramid. Can it be salvaged?

zeuspaul