ideas for different size balls

gardengal70

18 years ago

Related Stories

GREAT HOME PROJECTSWhat to Know About Adding a Backyard Bocce Ball Court

A regulation court in a relaxed setting helps you get the most from the Italian pastime. Here's what it takes to build one at home

Full Story

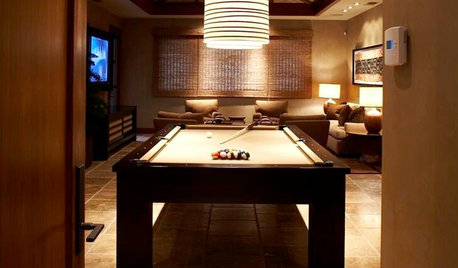

MORE ROOMSHave a Ball With Your Billiard Room

Decadently plush or based in a barn, these stunning billiard rooms show how much fun it is to take style cues from a pool table

Full Story

GARDENING AND LANDSCAPINGReflect on Your Garden's Mystery With Gazing Balls

Conjure a sense of magic with metallic garden spheres, which expand the view and your landscape's design potential

Full Story

GARDENING AND LANDSCAPINGLandscape Trends: Bocce Ball Courts

An ancient sport is a modern hit at home

Full Story

DECORATING GUIDESSingle Design Moves That Make All the Difference

One good turn deserves a whole ideabook — check out these exceptional lone moves that make the room

Full Story

LIGHTINGGuest Picks: Marching to a Different Drum Shade

Follow a designer as she hunts down the perfect light for her client

Full Story

FUN HOUZZSomething a Little Different: Fairy Houses

Miniature abodes crafted for otherworldly creatures capture the imagination

Full Story

COASTAL STYLESpin That Ship Wheel in a Different Style Direction

If overdone nautical kitsch has left you soaked, try these subtler and sophisticated looks for your captain's wheel

Full Story

MOST POPULARSee the Difference a New Back Deck Can Make

A dramatic 2-story porch becomes the centerpiece of this Ohio family’s renovated landscape

Full StorySponsored

rickharmer

gardengal70Original Author

Related Professionals

Deer Park Landscape Architects & Landscape Designers · Middle River Landscape Architects & Landscape Designers · Richmond Heights Landscape Architects & Landscape Designers · Salem Landscape Architects & Landscape Designers · Bethlehem Landscape Contractors · Lakeland Landscape Contractors · Concord Landscape Contractors · Danvers Landscape Contractors · Lemont Landscape Contractors · New Cassel Landscape Contractors · Parker Landscape Contractors · St. Louis Landscape Contractors · Streamwood Landscape Contractors · Waterford Landscape Contractors · Westford Landscape Contractorstango88

melissamary

ltd123

sleeplessinftwayne

rickharmer