Mower engine speed adjustment

williaea

17 years ago

Featured Answer

Sort by:Oldest

Comments (23)

canguy

17 years agolast modified: 9 years ago1saxman

17 years agolast modified: 9 years agoRelated Professionals

South Elgin Landscape Architects & Landscape Designers · Surprise Landscape Contractors · Bainbridge Island Landscape Contractors · Bell Gardens Landscape Contractors · Caldwell Landscape Contractors · Elkridge Landscape Contractors · Fort Worth Landscape Contractors · Indio Landscape Contractors · Lees Summit Landscape Contractors · Lynwood Landscape Contractors · University City Landscape Contractors · Wailuku Landscape Contractors · Carol City Carpenters · Parsippany Carpenters · The Hammocks Carpenterswilliaea

17 years agolast modified: 9 years agoxlindax

17 years agolast modified: 9 years agobill_kapaun

17 years agolast modified: 9 years agomattv21

17 years agolast modified: 9 years ago1saxman

17 years agolast modified: 9 years agomattv21

17 years agolast modified: 9 years agowilliaea

17 years agolast modified: 9 years agomattv21

17 years agolast modified: 9 years agoboeing747_comcast_net

15 years agolast modified: 9 years ago1saxman

15 years agolast modified: 9 years ago1saxman

15 years agolast modified: 9 years agooldlawnmowerman81

15 years agolast modified: 9 years agobill_kapaun

15 years agolast modified: 9 years agooldlawnmowerman81

15 years agolast modified: 9 years ago1saxman

15 years agolast modified: 9 years agooldlawnmowerman81

12 years agolast modified: 9 years agoHU-631019805

2 years ago1saxman

2 years agossewalk1

2 years agotomplum

2 years ago

Related Stories

ORGANIZINGGet Up to Speed for Back to School — 12 Tips for Smooth Sailing

New schedules and clothes, paperwork piles ... and where did all the Band-Aids go? These tips will help you ace the new school year

Full Story

KITCHEN DESIGN16 Practical Ideas to Borrow From Professional Kitchens

Restaurant kitchens are designed to function efficiently and safely. Why not adopt some of their tricks in your own home?

Full Story

GROUND COVERSGive Your Lawn a Taste of the Wild

Consider the joys of an irregularly trimmed meadow lawn: It’s ecofriendly, visually interesting and still good for romping

Full Story

GARAGESKey Measurements for the Perfect Garage

Get the dimensions that will let you fit one or more cars in your garage, plus storage and other needs

Full Story

ARCHITECTUREHouzz Tour: Sturdy Enough for a Tsunami

Storms don't scare this Washington state home; breakaway features and waterproof finishes let it weather high winds and waves

Full Story

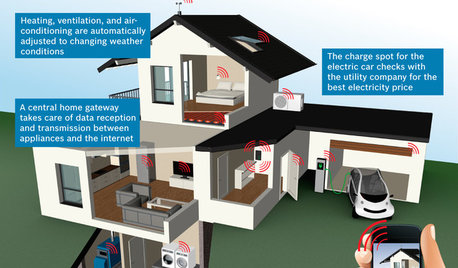

THE HARDWORKING HOMECES 2015: Inching Toward a Smarter Home

Companies are betting big on connected devices in 2015. Here’s a look at what’s to come

Full Story

GREEN BUILDINGHouzz Tour: Passive House in Vermont Slashes Heating Bills

Its ecofriendly, low-maintenance design leaves a family with more time to relax and enjoy the weekend home

Full Story

REMODELING GUIDESLaminate Floors: Get the Look of Wood (and More) for Less

See what goes into laminate flooring and why you just might want to choose it

Full Story

ACCESSORIESEasy Green: Cut Electricity Use With 15 Unplugged Home Devices

Crank up the energy savings, courtesy of household items that come into power the old-fashioned way: manually

Full Story

DESIGN PRACTICEDesign Practice: How to Pick the Right Drawing Software

Learn about 2D and 3D drawing tools, including pros, cons and pricing — and what to do if you’re on the fence

Full StoryMore Discussions

weed_cutter