Snapper Drive Disk Adjustment

blakeshawn

15 years ago

Featured Answer

Sort by:Oldest

Comments (13)

rustyj14

15 years agoblakeshawn

15 years agoRelated Professionals

New Bedford Landscape Architects & Landscape Designers · Erie Landscape Architects & Landscape Designers · Hartford Landscape Contractors · Brookline Landscape Contractors · Camp Verde Landscape Contractors · Mahwah Landscape Contractors · Mequon Landscape Contractors · River Ridge Landscape Contractors · West Orange Landscape Contractors · Arnold Carpenters · Bonita Springs Carpenters · Franconia Carpenters · Kissimmee Carpenters · The Hammocks Carpenters · Tucson Carpentersfix_it

15 years agowalt2002

15 years agoblakeshawn

15 years agowalt2002

15 years agoblakeshawn

15 years agoamigatec

15 years agoblakeshawn

15 years agowalt2002

15 years agoblakeshawn

15 years agoblakeshawn

15 years ago

Related Stories

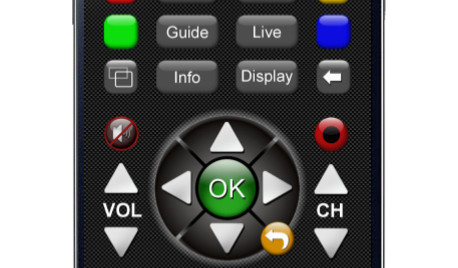

HOME TECHNew TV Remote Controls Promise to Do More — Without the Struggle

Dim your lights, set up user profiles and discover a remote you can't lose. Welcome to the latest and greatest way to change the channel

Full Story

DECORATING PROJECTSWhat to Do With Old Family Photos

Find out how to research, share and preserve images that offer a connection to the past

Full Story

MOST POPULAR9 Real Ways You Can Help After a House Fire

Suggestions from someone who lost her home to fire — and experienced the staggering generosity of community

Full Story

ARCHITECTURE15 Smart Design Choices for Cold Climates

Keep your home safe and comfortable in winter by choosing the right home features and systems

Full Story

BUDGET DECORATINGPop Culture Watch: Get a Good Rap With Thrift Store Scores

Eight rooms that rock secondhand finds, in an ideabook inspired by rappers taking YouTube by storm

Full Story

HOUSEKEEPINGThe Best Way to Get Your Windows Spotlessly Clean

Learn the pros’ tips and tricks for cleaning windows and getting them streak-free

Full Story

DECLUTTERINGFoolproof Ways to Declutter Your Kitchen

If you find yourself fumbling through cupboards to find what you’re looking for, it’s time to take action with these simple steps

Full Story

KITCHEN DESIGNHow to Pick a New Kitchen Faucet

Learn all about mounting styles, handles, finishes and quality to get the kitchen faucet that best fits your needs

Full Story

FEEL-GOOD HOMEBack Problems? Try Putting Your Feet Up

Consider these alternatives to that one-size-doesn’t-fit-all sofa to avoid slumping and spinal stress

Full Story

KITCHEN DESIGN91 Kitchen Banquettes to Start Your Morning Right

Slide into one of these stylish breakfast nooks and stay awhile

Full StorySponsored

Columbus Area's Luxury Design Build Firm | 17x Best of Houzz Winner!

More Discussions

blakeshawnOriginal Author