craftsman platinum 7.0 lawn mower wont stay running

pv.1961

10 years ago

Related Stories

LANDSCAPE DESIGN7 Low-Maintenance Lawn Alternatives

Turf isn't the only ground cover in town. Get a lush no-grass lawn with clover, moss and other easy-care plants

Full Story

LANDSCAPE DESIGNGet Along With Less Lawn — Ideas to Save Water and Effort

Ditch the mower and lower your water bill while creating a feast for the eyes with diverse plantings and gathering places

Full Story

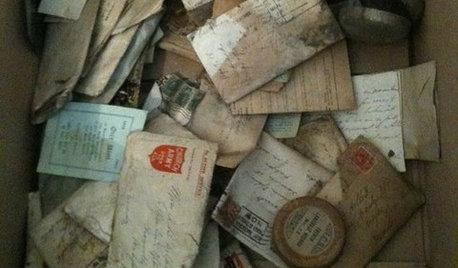

REMODELING GUIDESYou Won't Believe What These Homeowners Found in Their Walls

From the banal to the downright bizarre, these uncovered artifacts may get you wondering what may be hidden in your own home

Full Story

KITCHEN DESIGNStay Cool About Picking the Right Refrigerator

If all the options for refrigeration leave you hot under the collar, this guide to choosing a fridge and freezer will help you chill out

Full Story

ORGANIZINGDo It for the Kids! A Few Routines Help a Home Run More Smoothly

Not a Naturally Organized person? These tips can help you tackle the onslaught of papers, meals, laundry — and even help you find your keys

Full Story

BEFORE AND AFTERSSee 6 Yards Transformed by Losing Their Lawns

Wondering whether a turf lawn is the best use of your outdoor space? These homeowners did, and they found creative alternatives

Full Story

LANDSCAPE DESIGNCalifornia Says Goodbye to the Sprawling Ornamental Lawn

New state rules will effectively limit turfgrass to 25 percent of the landscape in most new and renovated yards

Full Story

FRONT YARD IDEASBefore and After: Front Lawn to Prairie Garden

How they did it: Homeowners create a plan, stick to it and keep the neighbors (and wildlife) in mind

Full Story

MONTHLY HOME CHECKLISTSOctober Checklist for a Smooth-Running Home

You're due for some winterizing, like clearing rain gutters and stowing swimsuits — but leave time for a fun project

Full Story

GROUND COVERSGive Your Lawn a Taste of the Wild

Consider the joys of an irregularly trimmed meadow lawn: It’s ecofriendly, visually interesting and still good for romping

Full Story

bill_kapaun

tomplum

Related Professionals

Forest Acres Landscape Architects & Landscape Designers · Finneytown Landscape Architects & Landscape Designers · Concord Landscape Contractors · Biloxi Landscape Contractors · Franklin Landscape Contractors · Golden Gate Landscape Contractors · Placerville Landscape Contractors · Vallejo Landscape Contractors · Atlanta Carpenters · Jamaica Plain Carpenters · Leander Carpenters · Lisle Carpenters · Margate Carpenters · Miami Springs Carpenters · San Marcos Carpenterspv.1961Original Author

baymee

pv.1961Original Author

tomplum

homegrown55

tomplum

1saxman

robertz6