Briggs & Stratton 4HP engine runs rough

gatwood

13 years ago

Related Stories

REMODELING GUIDESWhen to Use Engineered Wood Floors

See why an engineered wood floor could be your best choice (and no one will know but you)

Full Story

KITCHEN DESIGNKitchen Counters: Stunning, Easy-Care Engineered Quartz

There's a lot to like about this durable blend of quartz and resin for kitchen countertops, and the downsides are minimal

Full Story

DISASTER PREP & RECOVERYMore Power to You: How to Pick the Right Generator

If your home's electricity goes, don't let it take your necessities with it — keep systems running with this guide to backup power

Full Story

HOUZZ TOURSMy Houzz: Reinventing a 1930 Fire Station for Family Life

Don't sound the alarm because the fire engine is gone; this remodeled station now happily hosts fundraisers and two generations of a family

Full Story

HOUZZ TOURSMy Houzz: Polished Urban Sanctuary in Toronto

Suited perfectly to its working-class downtown neighborhood, an engineer's modern home is an airy and spacious retreat

Full Story

HOUZZ TOURSMy Houzz: Rustic Meets Refined in a Converted Ohio Barn

Intelligent reuse and innovative engineering create a modern family home that’s anything but typical

Full Story

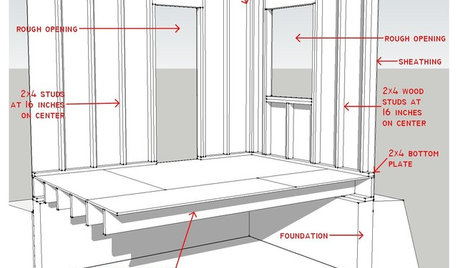

REMODELING GUIDESKnow Your House: Components of Efficient Walls

Learn about studs, rough openings and more in traditional platform-frame exterior walls

Full Story

WOODTry DIY Plywood Flooring for High Gloss, Low Cost

Yup, you heard right. Laid down and shined up, plywood can run with the big flooring boys at an affordable price

Full Story

LIFEWe Can Work It Out: Living (and Cleaning) Together

Run a household without fussing and fighting with these ideas for how to work together on household chores

Full Story

DECORATING GUIDESHow to Choose an Awesome Area Rug No Matter What Your Space

High use, a low door, kids and pets running amok — whatever your area endures, this insight will help you find the right rug for it

Full Story

baymee

rogelio_vargas_hotmail_com

Related Professionals

Lakewood Landscape Architects & Landscape Designers · Montgomeryville Landscape Architects & Landscape Designers · Saint Louis Park Landscape Architects & Landscape Designers · Newcastle Landscape Architects & Landscape Designers · Gainesville Landscape Contractors · Hartford Landscape Contractors · Springfield Landscape Contractors · Cambridge Landscape Contractors · Cary Landscape Contractors · East Lake-Orient Park Landscape Contractors · Fort Worth Landscape Contractors · Miller Place Landscape Contractors · Nutley Landscape Contractors · Weslaco Landscape Contractors · Mountain Home Carpentersbaymee

Nettar

joseph hubbard

1saxman