recoil has loose rope ???

fall

13 years ago

Related Stories

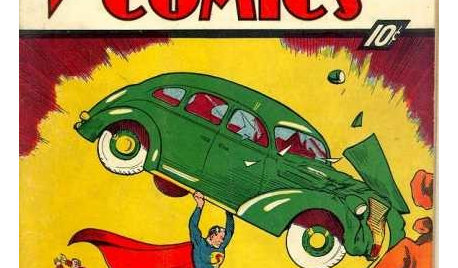

REMODELING GUIDESOne Guy Found a $175,000 Comic in His Wall. What Has Your Home Hidden?

Have you found a treasure, large or small, when remodeling your house? We want to see it!

Full Story

LIGHTINGThe Lowdown on High-Efficiency LED Lighting

Learn about LED tapes, ropes, pucks and more to create a flexible and energy-efficient lighting design that looks great

Full Story

DECORATING GUIDESHow to Channel Your Inner New Bohemian

Creative and artsy, unique and layered, these looks lead to an inspiring lifestyle at home

Full Story

DECORATING STYLESGypsy in Your Soul: 10 Steps to a Bohemian Bedroom

If your inner boho is clamoring to be released, feed your fantasies in a gorgeously unconventional bedroom

Full Story

GARDENING GUIDESGarden Myths to Debunk as You Dig This Fall and Rest Over Winter

Termites hate wood mulch, don’t amend soil for trees, avoid gravel in planters — and more nuggets of garden wisdom

Full Story

VICTORIAN DESIGNHouzz Tour: San Francisco’s Haas-Lilienthal House

Get a rare behind-the-scenes glimpse of this storied Victorian mansion from its decade-long caretaker

Full Story

ARCHITECTUREDutch Architects Balance the Familiar and the Avant-Garde

Peek inside a 2013 book to see bold new designs for modern living that never forget those living there

Full Story

PETSSo You Want to Get a Cat

If you're a cat lover, the joys outweigh any other issue. If you haven't lived with one yet, here are a few things to know

Full Story

FUN HOUZZ6 Reasons Every House Needs a Cat

Everyone should have a feline fixture as part of their home decor. Here's why

Full Story

ECLECTIC HOMESMy Houzz: A Treehouse-Like Dwelling in Los Angeles

Fragrant breezes, chirping birds and glorious sunsets provide a beautiful live-work setting for this design couple and their kids

Full Story

tomplum

baymee

Related Professionals

70037 Landscape Architects & Landscape Designers · Kyle Landscape Architects & Landscape Designers · Waterbury Landscape Contractors · Concord Landscape Contractors · Fort Wayne Landscape Contractors · Leicester Landscape Contractors · Oklahoma City Landscape Contractors · Quincy Landscape Contractors · Saint Paul Landscape Contractors · Welby Landscape Contractors · Selma Landscape Contractors · Escondido Carpenters · Goulds Carpenters · Snellville Carpenters · Temple Carpentersewalk

fallOriginal Author

baymee

lbpod

skyssx

fallOriginal Author

skyssx

andyma_gw