compression

jim109ny

13 years ago

Related Stories

GREEN BUILDINGWhy You Might Want to Build a House of Straw

Straw bales are cheap, easy to find and DIY-friendly. Get the basics on building with this renewable, ecofriendly material

Full Story

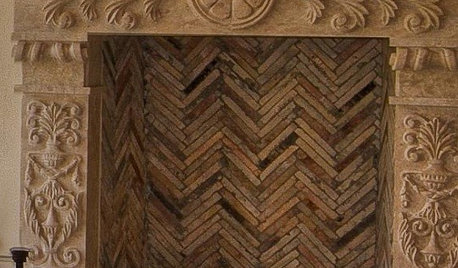

DESIGN DICTIONARYHerringbone

The herringbone pattern is composed of alternating rectangles arranged in zigzags

Full Story0

REMODELING GUIDESCharming Window Style Hinges on Hoppers

Hinged on the bottom and opening at the top, hopper windows are a great choice for bathrooms, basements and more

Full Story

TILESo Many Reasons to Love Cement Tiles

You’ll notice their beautiful patterns right away, but cement tiles have less obvious advantages too

Full Story

DECORATING GUIDESFelt Gives Rooms the Warm Fuzzies

Snuggle-up softness paired with workhorse sturdiness? It's no wonder felt has moved past crafts and onto interior design's radar

Full Story

FURNITUREKnow When to Fold 'Em

When space is tight, look for furniture that cleverly collapses, expands or fills more than one role

Full Story

DESIGN DICTIONARYGFRC

Glass fibers make this reinforced concrete lighter and slimmer for use in architecture and furniture

Full Story0

DESIGNER SHOWCASESA Kitchen Opens Up for a D.C. Show House

Removing a fieldstone wall helps turn a cooking space from dark and dingy to open and filled with light

Full Story

MORE ROOMSIdea of the Week: Driftwood Mantel

Green builders turn black walnut river log into one-of-a-kind accent piece

Full Story

GARDENING AND LANDSCAPINGShade Sails: Outdoor Rooms Take Wing

Futuristic looking yet a terrific complement to both traditional and modern landscapes, shade sails lend a sculptural quality to patios

Full StoryMore Discussions

baymee

jim109nyOriginal Author

Related Professionals

Hyattsville Landscape Architects & Landscape Designers · North New Hyde Park Landscape Architects & Landscape Designers · Willowick Landscape Architects & Landscape Designers · Tempe Landscape Contractors · Cupertino Landscape Contractors · El Mirage Landscape Contractors · El Reno Landscape Contractors · Fairfield Landscape Contractors · Lewisville Landscape Contractors · Manhattan Landscape Contractors · Red Oak Landscape Contractors · Baileys Crossroads Landscape Contractors · Clearfield Landscape Contractors · Killeen Carpenters · Valdosta Carpentersbaymee

walt2002

orangedotfever

roadbike

ewalk

ewalk

baymee

jim109nyOriginal Author

walt2002

orangedotfever

ewalk

orangedotfever

ewalk

1saxman

ewalk

orangedotfever

lbpod

baymee

lbpod

baymee

lbpod

ewalk

walt2002

orangedotfever

orangedotfever

baymee

orangedotfever

ewalk

jim109nyOriginal Author

walt2002

baymee

ewalk

walt2002

bogman

orangedotfever

walt2002

orangedotfever

ewalk

orangedotfever

ewalk

roadbike

ewalk

roadbike

orangedotfever

ewalk

jim109nyOriginal Author

baymee