turning geodesic dome into greenhouse

adlumia_fungosum

10 years ago

Related Stories

LANDSCAPE DESIGN10 Fun Features to Bring Your Landscape to Life

Give gnomes a home, create a magical portal or add another unexpected element to turn your garden into a destination

Full Story

REMODELING GUIDESGive Me a Wall, a Roof, or a House of Glass

Swoon over spaces warmed by sunlight — from one side, or many

Full Story

HOUZZ TVHouzz TV: This Dream Midcentury Home in a Forest Even Has Its Own Train

Original wood ceilings, a cool layout and, yes, a quarter-scale train persuaded these homeowners to take a chance on a run-down property

Full Story

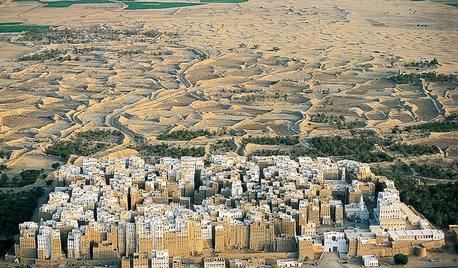

EVENTSOn Show: The Ingenuity of Ancient Architecture

A German exhibit celebrates the diversity of traditional homes built with materials at hand

Full Story

GREAT HOME PROJECTSHow to Add a Skylight or Light Tube

New project for a new year: Increase daylight and maybe even your home’s energy efficiency by opening a room to the sky

Full Story

ARCHITECTUREHow Thermal Mass Keeps You Warm and Cool

Passive solar design makes use of this element. Here’s how it works and how you can get it in your home

Full Story

DREAM SPACESJust a Few Things for the Dream-Home Wish List

A sunken hot tub, dedicated game room, tree house, hidden wine cellar and more. Which of these home luxuries would you like best?

Full Story

ARCHITECTUREBack to the Futuro: Tour a Lovingly Restored ‘Spaceship’ Home

Travel back to the ’60s Space Age with a rare glimpse inside an original House of the Future

Full Story

CONTEMPORARY HOMESHouzz Tour: Later in Life, a Bold New Design Adventure

A Washington, D.C., couple in their 70s embark on a new marriage and an innovative renovation of a historic row house

Full Story

GARDENING AND LANDSCAPINGHow to Make a Pond

You can make an outdoor fish paradise of your own, for less than you might think. But you'll need this expert design wisdom

Full Story

barrie2m_(6a, central PA)

adlumia_fungosumOriginal Author

Related Professionals

North New Hyde Park Landscape Architects & Landscape Designers · Lakeland Landscape Contractors · Maple Valley Landscape Contractors · Braintree Landscape Contractors · Camp Verde Landscape Contractors · Hampton Bays Landscape Contractors · Long Beach Landscape Contractors · Morrisville Landscape Contractors · Pahrump Landscape Contractors · Paterson Landscape Contractors · Brentwood Los Angeles Solar Energy Systems · Fort Lee Solar Energy Systems · Frankfort Solar Energy Systems · Gardena Solar Energy Systems · Moorpark Solar Energy Systemsbarrie2m_(6a, central PA)

adlumia_fungosumOriginal Author

barrie2m_(6a, central PA)

steve333_gw

User

petrushka (7b)

hex2006