Blue Flame heater won't stay lit

kurtos

12 years ago

Featured Answer

Sort by:Oldest

Comments (11)

poppa

12 years agolast modified: 9 years agogreen_grandma

12 years agolast modified: 9 years agoRelated Professionals

Wrentham Landscape Architects & Landscape Designers · Surprise Landscape Architects & Landscape Designers · Salem Landscape Contractors · Blue Springs Landscape Contractors · Fort Atkinson Landscape Contractors · Middletown Landscape Contractors · Oakland Landscape Contractors · Oklahoma City Landscape Contractors · El Mirage Solar Energy Systems · Gardena Solar Energy Systems · Green Valley Solar Energy Systems · Holliston Solar Energy Systems · Oakland Solar Energy Systems · Randolph Solar Energy Systems · Verona Solar Energy Systemssandy0225

11 years agolast modified: 9 years agoetravian

11 years agolast modified: 9 years agokurtos

11 years agolast modified: 9 years agoScott L

8 years agokurtos

8 years agoScott L

8 years agokurtos

8 years agoScott L

8 years ago

Related Stories

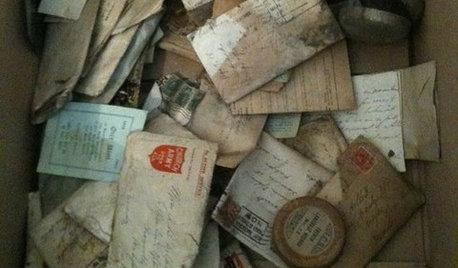

REMODELING GUIDESYou Won't Believe What These Homeowners Found in Their Walls

From the banal to the downright bizarre, these uncovered artifacts may get you wondering what may be hidden in your own home

Full Story

GREAT HOME PROJECTSHow to Switch to a Tankless Water Heater

New project for a new year: Swap your conventional heater for an energy-saving model — and don’t be fooled by misinformation

Full Story

MOST POPULARIs Open-Plan Living a Fad, or Here to Stay?

Architects, designers and Houzzers around the world have their say on this trend and predict how our homes might evolve

Full Story

DECLUTTERINGDecluttering — Don't Let Fear Hold You Back

Sure, you might make a mistake when tackling a decluttering project, but that's OK. Here's why

Full Story

DINING ROOMSNew This Week: Proof the Formal Dining Room Isn’t Dead

Could graphic wallpaper, herringbone-patterned floors, wine cellars and fire features save formal dining rooms from extinction?

Full Story

LIVING ROOMSLiving Rooms That Don’t Revolve Around the TV

In these spaces, the television takes a back seat to conversation, relaxation and aesthetics

Full Story

BLUEIs Midnight Blue the New Black?

As bold as black but much more versatile, midnight blue is becoming a star

Full Story

BLUE9 Beautiful Blues for Bathrooms

From soft sky to bold tropical aqua, see why this hue is making waves in bathrooms

Full Story

BATHROOM COLOR8 Ways to Spruce Up an Older Bathroom (Without Remodeling)

Mint tiles got you feeling blue? Don’t demolish — distract the eye by updating small details

Full Story

FURNITUREForever Furniture: A Buyer’s Guide to the Dining Table

There comes a time when a make-do piece of furniture won’t do. We give you a leg up on choosing the right table for you

Full Story

kurtosOriginal Author