Inspect My Greenhouse Plans Please

BillsBayou

13 years ago

Related Stories

CONTRACTOR TIPSBuilding Permits: The Final Inspection

In the last of our 6-part series on the building permit process, we review the final inspection and typical requirements for approval

Full Story

MOVINGHome-Buying Checklist: 20 Things to Consider Beyond the Inspection

Quality of life is just as important as construction quality. Learn what to look for at open houses to ensure comfort in your new home

Full Story

Houzz Call: Show Us Your Greenhouse

Submit a photo of your greenhouse and share what's growing!

Full Story

OUTBUILDINGSStudio Solution: A Kit Greenhouse Becomes a Creative Private Office

See how an inventive work-from-home designer made an office from a greenhouse, for some inspired thinking in the backyard

Full Story

GARDENING AND LANDSCAPINGSee a Family Greenhouse Grown From Scraps

Can-do resourcefulness and less than $400 lead to a new 8- by 8-foot home for plants on a Tennessee family's property

Full Story

FARM YOUR YARDAn Urban Greenhouse Overflows With Edibles

Making meals just means stepping into the yard for a San Francisco couple who revamped an old orchid house

Full Story

HOUSEKEEPING7-Day Plan: Get a Spotless, Beautifully Organized Garage

Stop fearing that dirty dumping ground and start using it as the streamlined garage you’ve been wanting

Full Story

BATHROOM DESIGNConvert Your Tub Space to a Shower — the Planning Phase

Step 1 in swapping your tub for a sleek new shower: Get all the remodel details down on paper

Full Story

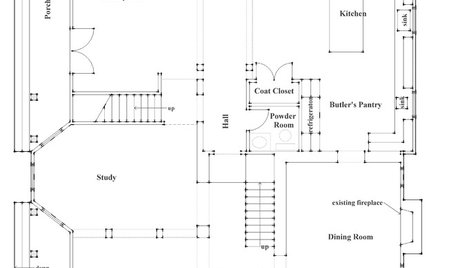

REMODELING GUIDESHow to Read a Floor Plan

If a floor plan's myriad lines and arcs have you seeing spots, this easy-to-understand guide is right up your alley

Full Story

HOUSEKEEPINGChoose Your Own Spring Cleaning Plan

Instead of trying to do it all, pick one of these six cleaning approaches that’s right for you now

Full Story

hdcochran

hdcochran

Related Professionals

Norfolk Landscape Architects & Landscape Designers · Accokeek Landscape Architects & Landscape Designers · Middle Island Landscape Architects & Landscape Designers · Amesbury Landscape Contractors · Cupertino Landscape Contractors · Inglewood Landscape Contractors · Mason Landscape Contractors · McLean Landscape Contractors · Mission Landscape Contractors · New Cassel Landscape Contractors · Raleigh Landscape Contractors · Snoqualmie Landscape Contractors · South Lyon Landscape Contractors · Tamarac Landscape Contractors · Fontana Solar Energy SystemsBillsBayouOriginal Author

hdcochran