PVC framing

hairmetal4ever

9 years ago

Related Stories

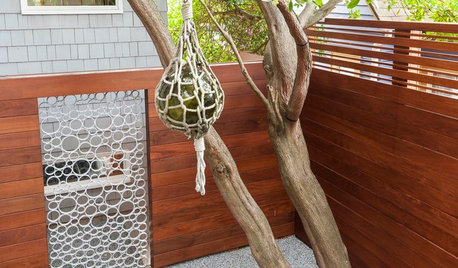

FENCES AND GATESA Designer Uses PVC Pipe to Cast a Modern Garden Gate

Landscape designer Scot Eckley walks us through the process of creating a custom aluminum ring gate

Full Story

WINTER GARDENINGExtend Your Growing Season With a Cold Frame in the Garden

If the sun's shining, it might be time to sow seeds under glass to transplant or harvest

Full Story

WINDOWSFrame the View with Divided-Light Windows

Multi-pane windows add architectural interest to rooms of any style

Full Story

GARDENING AND LANDSCAPINGHow to Keep Your Outdoor Furniture Looking New

Give cushions and wicker, teak or metal frames a little regular TLC to help them last

Full Story

MOST POPULARHow to Start a Cool-Season Vegetable Garden

Late summer and late winter are good times to plan and plant cool-season crops like salad greens, spinach, beets, carrots and peas

Full Story

LIGHTINGHouse Hunting? Look Carefully at the Light

Consider windows, skylights and the sun in any potential home, lest you end up facing down the dark

Full Story

FARM YOUR YARDCool-Season Vegetables: How to Grow Lettuce

Leaf, butterhead, crisphead or romaine — lettuce is best harvested in the cool weather of spring and fall

Full Story

HOUSEKEEPINGAnother Independence Day: When Kids Can Do Their Laundry

Set yourself free and give your child a valuable life skill at the same time

Full Story

FENCES AND GATESHow to Install a Wood Fence

Gain privacy and separate areas with one of the most economical fencing choices: stained, painted or untreated wood

Full StoryMore Discussions

barrie2m_(6a, central PA)

CanadianLori

Related Professionals

Birmingham Landscape Architects & Landscape Designers · Foothill Ranch Landscape Architects & Landscape Designers · New Mexico Landscape Architects & Landscape Designers · Rancho Cordova Landscape Architects & Landscape Designers · Wheeling Landscape Architects & Landscape Designers · Williamsburg Landscape Contractors · Bedford Heights Landscape Contractors · Bedford Landscape Contractors · Golden Gate Landscape Contractors · Mount Sinai Landscape Contractors · Newnan Landscape Contractors · Rio Linda Landscape Contractors · Yuba City Landscape Contractors · Chicago Ridge Landscape Contractors · Goldenrod Landscape ContractorsCanadianLori

CanadianLori

cole_robbie

szut (Zone 6 - MA)