making a compost tumbler from a water heater...maybe

clarysage1717

18 years ago

Featured Answer

Comments (13)

Related Stories

GREAT HOME PROJECTSHow to Switch to a Tankless Water Heater

New project for a new year: Swap your conventional heater for an energy-saving model — and don’t be fooled by misinformation

Full Story

GREAT HOME PROJECTSHow to Add a Solar Water Heater

Lower energy bills without a major renovation by putting the sun to work heating your home’s water

Full Story

GARDENING GUIDESGet on a Composting Kick (Hello, Free Fertilizer!)

Quit shelling out for pricey substitutes that aren’t even as good. Here’s how to give your soil the best while lightening your trash load

Full Story

HEALTHY HOMEHow to Keep Water Vapor From Ruining Your House and Your Health

We help you find out when it’s happening, what it means and how to fix it

Full Story

GARDENING GUIDESHouzz TV: Make a Worm Bin for Rich Soil and Happy Plants

A worm-powered compost bin that can fit under a sink turns food scraps into a powerful amendment for your garden. Here’s how to make one

Full Story

LIFE11 Tiny Tricks That Make Life a Tad Better

Make these small tweaks to your home and daily routine, and life will be easier, less rushed and maybe healthier too

Full Story

GARDENING FOR BUTTERFLIES3 Ways Native Plants Make Gardening So Much Better

You probably know about the lower maintenance. But native plants' other benefits go far beyond a little less watering and weeding

Full Story

MOST POPULARSo You Say: 30 Design Mistakes You Should Never Make

Drop the paint can, step away from the brick and read this remodeling advice from people who’ve been there

Full Story

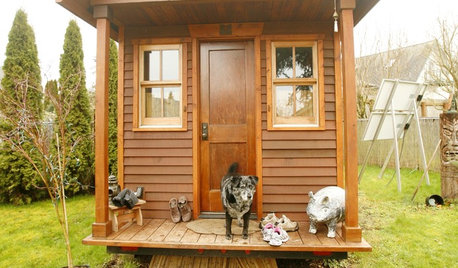

SMALL SPACESLife Lessons From 10 Years of Living in 84 Square Feet

Dee Williams was looking for a richer life. She found it by moving into a very tiny house

Full Story

GREEN DECORATINGEasy Green: Big and Small Ways to Be More Water-Wise at Home

These 20 tips can help us all make the best use of a precious resource. How do you save water in summer?

Full StoryMore Discussions

john_c