Do you pressure wash any parts of your chainsaw assembled

loger_gw

12 years ago

Related Stories

HOUSEKEEPINGHow to Wash Your House

Avoid damage to siding and plants while getting your home's exterior shining clean, with this guide to using pressure washers and hoses

Full Story

LANDSCAPE DESIGNKoi Find Friendly Shores in Any Garden Style

A pond full of colorful koi can be a delightful addition to just about any landscape or garden

Full Story

HOLIDAYSSet the Scene for a Stress-Free Holiday Visit

Put your guests at ease and take the pressure off hosting by prepping your space with psychology in mind

Full Story

KITCHEN DESIGNButcher Block Makes the Cut for Holiday Kitchen Prep

Countertops and cutting boards will likely take a beating over the holidays. These butcher blocks have the chops to perform under pressure

Full Story

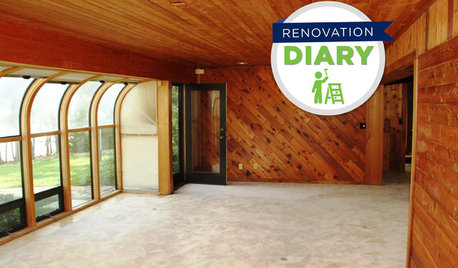

REMODELING GUIDESPlan Your Home Remodel: The Design and Drawing Phase

Renovation Diary, Part 2: A couple has found the right house, a ranch in Florida. Now it's time for the design and drawings

Full Story

MOST POPULAR10 Smart Ideas for Your Laundry Room Remodel

Make washing and drying easier and more comfortable by considering ergonomics, storage and special features

Full Story

LAUNDRY ROOMSClever Ways to Hide a Laundry Station

When you don’t have a whole room to devote to the wash, use these solutions to tuck the machines out of view

Full Story

THE HARDWORKING HOMEWhere to Put the Laundry Room

The Hardworking Home: We weigh the pros and cons of washing your clothes in the basement, kitchen, bathroom and more

Full Story

HEALTHY HOME12 Ways to Set Up Your Kitchen for Healthy Eating

Making smart food choices is easier when your kitchen is part of your support team

Full Story

HOUSEKEEPINGIt’s Time to Clean Your Gutters — Here’s How

Follow these steps to care for your gutters so they can continue to protect your house

Full Story

nod702

mla2ofus

Related Professionals

Piqua Landscape Architects & Landscape Designers · Harvey Landscape Architects & Landscape Designers · Alexandria Landscape Contractors · Matthews Landscape Contractors · Forest Hills Landscape Contractors · Gaithersburg Landscape Contractors · Suitland Landscape Contractors · Boynton Beach Decks, Patios & Outdoor Enclosures · Fort Pierce Decks, Patios & Outdoor Enclosures · Gaithersburg Decks, Patios & Outdoor Enclosures · North Aurora Decks, Patios & Outdoor Enclosures · Rogers Decks, Patios & Outdoor Enclosures · Rossmoor Home Builders · South Sioux City Home Builders · Parkway Home Buildersewalk

txtom50

rcmoser

loger_gwOriginal Author

loger_gwOriginal Author

rcmoser