string trimmer eats string

kookoo2

12 years ago

Related Stories

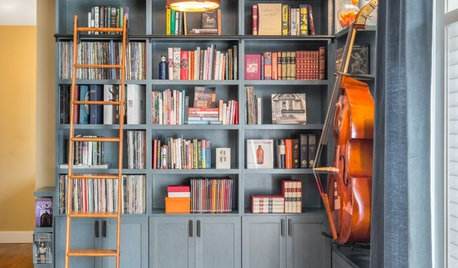

THE HARDWORKING HOMEFrom Awkward Corner to Multipurpose Lounge

The Hardworking Home: See how an empty corner becomes home to a library, an LP collection, a seating area and a beloved string bass

Full Story

EDIBLE GARDENSHow to Cultivate a Young Gardener

Want your kids to eat their vegetables? Let them have an edible garden of their own. Here are some tips on gardening with children

Full Story

HOLIDAYSHouzz Call: Share Your Favorite Christmas Tradition

Is there one thing you do, watch or eat that heralds the arrival of Christmas? Post a photo and let us know!

Full Story

KITCHEN DESIGNGoodbye, Island. Hello, Kitchen Table

See why an ‘eat-in’ table can sometimes be a better choice for a kitchen than an island

Full Story

SHOP HOUZZShop Houzz: Backyard Entertaining Essentials

Have some fun in the sun with party lights, pool floats, tableware and outdoor furniture

Full Story0

LIFE8 Home Projects Perfect for Holiday Downtime

Start the new year on the right foot by using some free time now to organize, store and clean

Full Story

FURNITUREWhich Dining Table Shape Should You Choose?

Rectangular, oval, round or square: Here are ways to choose your dining table shape (or make the most of the one you already have)

Full Story

KITCHEN DESIGNKitchen Remodel Costs: 3 Budgets, 3 Kitchens

What you can expect from a kitchen remodel with a budget from $20,000 to $100,000

Full Story

VACATION HOMESHouzz Tour: A French Ski Chalet’s Dark Sophistication

A superstylish ski chalet is layered with tactile surfaces, organic textures and warm colors

Full StoryMore Discussions

rcmoser

kookoo2Original Author

rustyj14

rcmoser

rcmoser

tomplum