9hp VanGuard is VERY Hard to Start

treefrog99

16 years ago

Related Stories

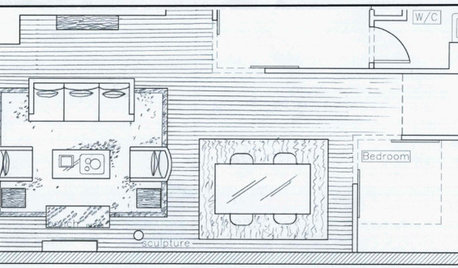

DECORATING GUIDES9 Planning Musts Before You Start a Makeover

Don’t buy even a single chair without measuring and mapping, and you’ll be sitting pretty when your new room is done

Full Story

LIFEHard Winter? 9 Ways to Battle Cabin Fever

We know a lot of you are trapped where it just won’t stop snowing. Here are some ways to survive

Full Story

REMODELING GUIDES9 Hard Questions to Ask When Shopping for Stone

Learn all about stone sizes, cracks, color issues and more so problems don't chip away at your design happiness later

Full Story

MOST POPULAR10 Things to Ask Your Contractor Before You Start Your Project

Ask these questions before signing with a contractor for better communication and fewer surprises along the way

Full Story

GARDENING GUIDES10 Tips to Start a Garden — Can-Do Ideas for Beginners

Green up your landscape even if you're short on time, money and knowledge, with these manageable steps for first-time gardeners

Full Story

REMODELING GUIDESWhat to Consider Before Starting Construction

Reduce building hassles by learning how to vet general contractors and compare bids

Full Story

KITCHEN DESIGNStylish New Kitchen, Shoestring Budget: See the Process Start to Finish

For less than $13,000 total — and in 34 days — a hardworking family builds a kitchen to be proud of

Full Story

DECORATING GUIDESDecorating 101: How to Start a Decorating Project

Before you grab that first paint chip, figure out your needs, your decorating style and what to get rid of

Full Story

FARM YOUR YARD6 Things to Know Before You Start Growing Your Own Food

It takes time and practice, but growing edibles in the suburbs or city is possible with smart prep and patience

Full Story

KITCHEN DESIGN91 Kitchen Banquettes to Start Your Morning Right

Slide into one of these stylish breakfast nooks and stay awhile

Full StoryMore Discussions

treefrog99Original Author

bill_kapaun

Related Professionals

Ashburn Landscape Architects & Landscape Designers · Jackson Landscape Contractors · Andover Landscape Contractors · Fuquay-Varina Landscape Contractors · Glendale Heights Landscape Contractors · Kettering Landscape Contractors · Northport Landscape Contractors · Spring Landscape Contractors · Winter Gardens Landscape Contractors · Shorewood Decks, Patios & Outdoor Enclosures · Meridian Decks, Patios & Outdoor Enclosures · Spanaway Decks, Patios & Outdoor Enclosures · Glenpool Home Builders · Manassas Home Builders · Waimalu Home Buildersmelee5

tomplum

rcmoser

treefrog99Original Author

bill_kapaun

treefrog99Original Author

treefrog99Original Author

treefrog99Original Author

fisher40037

treefrog99Original Author

bill_kapaun

jerry_nj

treefrog99Original Author

rustyj14

treefrog99Original Author

let_ca