Aluminum repair ( brazing rods ) ?

rkpatt

14 years ago

Related Stories

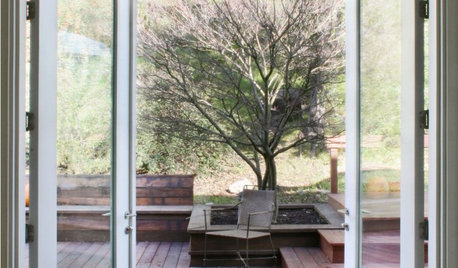

MOST POPULARFind the Right Glass Door for Your Patio

It’s more than just a patio door — it’s an architectural design element. Here’s help for finding the right one for your home and lifestyle

Full Story

CONCRETEWhy Concrete Wants to Crack

We look at the reasons concrete has a tendency to crack — and what you can do to help control it

Full Story

GREAT HOME PROJECTSHow to Replace or Revamp Your Garage Doors

Boost curb appeal and maybe even security with new garage doors. Find out cost ranges and other important details here

Full Story

DECORATING GUIDESYour Guide to Window Treatments

The right window treatments can provide privacy, light control and safety — or just better style

Full Story

MOST POPULARA Contractor's Secrets to Hanging Holiday Decor

Hang a wreath or garland on brick, concrete, Sheetrock or wood the professional way — and avoid the potential pitfalls

Full Story

KITCHEN WORKBOOK8 Kitchen Amenities You'll Really Wish You Had

Keep kitchen mayhem and muck to a minimum with these terrific organizers and other time-saving, mess-preventing features

Full Story

MOST POPULAR5 Ways to Hide That Big Air Conditioner in Your Yard

Don’t sweat that boxy A/C unit. Here’s how to place it out of sight and out of mind

Full Story

LIFEYou Showed Us: 20 Nutty Home Fixes

We made the call for your Band-Aid solutions around the house, and you delivered. Here's how you are making what's broken work again

Full Story

GREAT HOME PROJECTSHow to Add a Skylight or Light Tube

New project for a new year: Increase daylight and maybe even your home’s energy efficiency by opening a room to the sky

Full Story

WINDOW TREATMENTSEasy Green: 9 Low-Cost Ways to Insulate Windows and Doors

Block drafts to boost both warmth and energy savings with these inexpensive but effective insulating strategies

Full StorySponsored

Custom Craftsmanship & Construction Solutions in Franklin County

More Discussions

kompressor

lbpod

Related Professionals

Alexandria Landscape Contractors · Arlington Landscape Contractors · Blue Springs Landscape Contractors · Burien Landscape Contractors · Cincinnati Landscape Contractors · Hicksville Landscape Contractors · North Potomac Landscape Contractors · Wethersfield Landscape Contractors · Wickliffe Landscape Contractors · Brookfield Decks, Patios & Outdoor Enclosures · Chicago Decks, Patios & Outdoor Enclosures · Foothill Farms Decks, Patios & Outdoor Enclosures · Grandview Decks, Patios & Outdoor Enclosures · Big Bear City Home Builders · Kingsburg Home Buildersgator_rider2

rustyj14