compressor won't start

hut123

18 years ago

Related Stories

REMODELING GUIDESYou Won't Believe What These Homeowners Found in Their Walls

From the banal to the downright bizarre, these uncovered artifacts may get you wondering what may be hidden in your own home

Full Story

SMALL SPACES10 Tiny Kitchens Whose Usefulness You Won't Believe

Ingenious solutions from simple tricks to high design make this roundup of small kitchens an inspiring sight to see

Full Story

LIFEYou Said It: ‘Put It Back’ If It Won’t Help Your House, and More Wisdom

Highlights from the week include stopping clutter from getting past the door, fall planting ideas and a grandfather’s gift of love

Full Story

HOME TECH3 Kitchen Contraptions You Won’t Believe

Pizza hot from the printer, anyone? These cooking gadgets harness imagination and high tech — and have price tags to match

Full Story

MORE ROOMSWhere to Put the TV When the Wall Won't Work

See the 3 Things You'll Need to Float Your TV Away From the Wall

Full Story

BUDGET DECORATING15 Summery Decorating Ideas That Won't Break the Bank

Transport yourself seaside with a bit of paint or a few airy accessories

Full Story

ENTRYWAYSOrganizing Starts at the Door

You don't need fancy bins and containers to keep your entryway tidy — just a system that sticks

Full Story

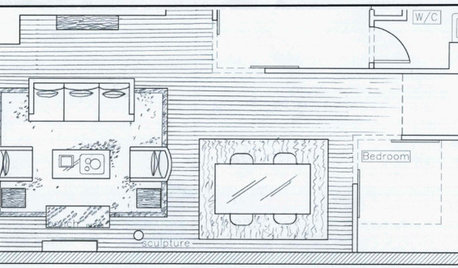

DECORATING GUIDES9 Planning Musts Before You Start a Makeover

Don’t buy even a single chair without measuring and mapping, and you’ll be sitting pretty when your new room is done

Full Story

ARCHITECTURESee the Daring Experimentalist Who Won 2013's Pritzker Prize

Architecture's highest honor goes to someone with a diverse and complex body of work and a never-satisfied mind-set

Full Story

mikie_gw

mla2ofus

Related Professionals

Reading Landscape Architects & Landscape Designers · Forest Park Landscape Architects & Landscape Designers · Horsham Landscape Architects & Landscape Designers · Rancho Palos Verdes Landscape Architects & Landscape Designers · Woodinville Landscape Architects & Landscape Designers · Surprise Landscape Contractors · Americus Landscape Contractors · Fairview Landscape Contractors · Fort Atkinson Landscape Contractors · Fuquay-Varina Landscape Contractors · River Ridge Landscape Contractors · Tuscaloosa Landscape Contractors · Alvin Decks, Patios & Outdoor Enclosures · Orange County Decks, Patios & Outdoor Enclosures · Rocklin Decks, Patios & Outdoor Enclosureshut123Original Author

mla2ofus

earthworm

bambooo

eurolarva

hut123Original Author

mla2ofus

canguy

green_valley

kbeitz

bigal_mo

hut123Original Author

hut123Original Author

bigal_mo