New Ryobi S430 engine dies on full throttle

losrubios

15 years ago

Featured Answer

Comments (49)

weed_cutter

15 years agolast modified: 9 years agowfreeman

15 years agolast modified: 9 years agoRelated Professionals

Camas Landscape Architects & Landscape Designers · Rancho Palos Verdes Landscape Architects & Landscape Designers · Newcastle Landscape Architects & Landscape Designers · Milford Landscape Contractors · Euclid Landscape Contractors · Harrisburg Landscape Contractors · North Highlands Landscape Contractors · Antioch Landscape Contractors · Bellingham Decks, Patios & Outdoor Enclosures · Brookfield Decks, Patios & Outdoor Enclosures · Foothill Farms Decks, Patios & Outdoor Enclosures · Fredericksburg Decks, Patios & Outdoor Enclosures · Rancho Palos Verdes Decks, Patios & Outdoor Enclosures · Syracuse Home Builders · West Jordan Home Builderslosrubios

15 years agolast modified: 9 years agomike_kuehn

14 years agolast modified: 9 years agowillyk

13 years agolast modified: 9 years agorpura

13 years agolast modified: 9 years agoswilliesims_aol_com

13 years agolast modified: 9 years agojetjerkstevo_aol_com

12 years agolast modified: 9 years agodocdavidb

12 years agolast modified: 9 years agocback81_hotmail_com

12 years agolast modified: 9 years agoiamsaws

12 years agolast modified: 9 years agotwinz1978_yahoo_com

12 years agolast modified: 9 years agocmce9_yahoo_com

12 years agolast modified: 9 years agorustyj14

12 years agolast modified: 9 years agoBDSolarMan

12 years agolast modified: 9 years agoSludgeMan

12 years agolast modified: 9 years agojimandnena

12 years agolast modified: 9 years agojimandnena

12 years agolast modified: 9 years agomickey223

12 years agolast modified: 9 years agoJoJo001

11 years agolast modified: 9 years agoRadioHam

10 years agolast modified: 9 years agoRadioHam

10 years agolast modified: 9 years agoStihlGoldTec

10 years agolast modified: 9 years agosranke

10 years agolast modified: 9 years agoTejas1961

10 years agolast modified: 9 years agotonyski

9 years agolast modified: 9 years agothe_0utsider

9 years agolast modified: 9 years agohippy

9 years agolast modified: 9 years agotonyski

9 years agolast modified: 9 years agoJalfrezi

9 years agolast modified: 9 years agokakirkla1

9 years agoErnesto Mejiaortega

8 years agologer_gw

8 years agodangerbug

8 years agoNorthwester

8 years agomartinmotors2

8 years agorustyj14

8 years agoboothgr

8 years agoGeorge Boshell

7 years agoScott Eldredge

7 years agoKevin Gunn

6 years agoclairee1

6 years agomarkwys

6 years agorbchoke6

6 years agossewalk1

6 years agomdstamen

6 years agossewalk1

6 years agolast modified: 6 years agoJoe Nejedly

last year

Related Stories

HOUZZ TOURSMy Houzz: Home Full of Boys Achieves Order and Inspiration

A 3-month overhaul produces an organized and inviting space fit for this Florida family of 9

Full Story

DREAM SPACESHouzz Tour: Hugging the Rocky Cliffs in Big Sur

Cascading down a rugged site and generously encased in glass, this California home takes full advantage of its ocean views

Full Story

VINTAGE STYLEAntique Sewing Machines: Tailor Made for Nostalgic Decor

In full-on vintage rooms or contrasting modern looks, old sewing machines and tables are stirring up the past in a most stylish way

Full Story

HOUZZ TOURSHouzz Tour: Sleek San Francisco Getaway

Spectacular Views Inspire a Renovation 'Full of Promise and Theater'

Full Story

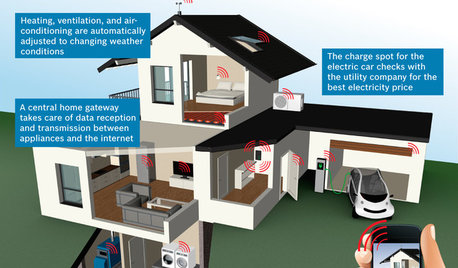

THE HARDWORKING HOMECES 2015: Inching Toward a Smarter Home

Companies are betting big on connected devices in 2015. Here’s a look at what’s to come

Full Story

GARDENING AND LANDSCAPINGHouzz Tour: An Aussie Pavilion Throws Its Home a Curve

A pavilion, a chef’s kitchen and plenty of poolside dining create an entertainer’s haven for one happy family

Full Story

HOUZZ TOURSMy Houzz: An Orange County Ranch Gets Into the Swing of Things

Golf course views and a mild climate feature in this 1960s ranch remodeled in midcentury modern style

Full Story

GARDENING GUIDESGet on a Composting Kick (Hello, Free Fertilizer!)

Quit shelling out for pricey substitutes that aren’t even as good. Here’s how to give your soil the best while lightening your trash load

Full Story

HOUZZ TOURSMy Houzz: Color This Utah Home Terrific

Candy-colored walls lit up by sunlight and a streamlined, open layout make a family’s new house one of a kind

Full Story

HOUZZ TOURSHouzz Tour: Stunning Desert Hillside Home in Arizona

An extraordinary, expansive home near Phoenix celebrates and interacts with the beauty of its natural surroundings

Full StoryMore Discussions

docdavidb