Left the tiller switch in 'Run' position

mikkyle

12 years ago

Related Stories

LIGHTINGWhat to Know About Switching to LED Lightbulbs

If you’ve been thinking about changing over to LEDs but aren't sure how to do it and which to buy, this story is for you

Full Story

WORKING WITH PROSYour Guide to a Smooth-Running Construction Project

Find out how to save time, money and your sanity when building new or remodeling

Full Story

LIVING ROOMSHow to Convert Your Wood-Burning Fireplace

Learn about inserts and other options for switching your fireplace from wood to gas or electric

Full Story

LIFETips for Moving Into a Smaller Space

Downsize with less compromise: Celebrate the positive, pare down thoughtfully and get the most from your new home

Full Story

BATHROOM MAKEOVERSRoom of the Day: Bathroom Embraces an Unusual Floor Plan

This long and narrow master bathroom accentuates the positives

Full Story

BATHROOM DESIGNPowder Room Essentials to Keep Guests Happy

Set out these bathroom necessities (hello, hand towels) to make your company comfortable and your parties run smoothly

Full Story

REMODELING GUIDES10 Things to Do Before the Renovation Begins

Prep and plan with this insight in hand to make your home remodeling project run more smoothly

Full Story

PETSSee a Deluxe 'Catio' Built for Feline Fun

Sixteen lucky cats get the run of a protected outdoor patio with ramps, steps and even a koi pond

Full Story

SAVING WATER11 Ways to Save Water at Home

Whether you live in a drought-stricken area or just want to help preserve a precious resource, here are things you can do to use less water

Full Story

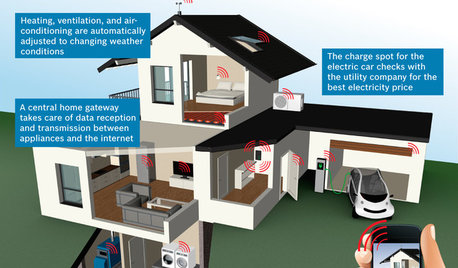

THE HARDWORKING HOMECES 2015: Inching Toward a Smarter Home

Companies are betting big on connected devices in 2015. Here’s a look at what’s to come

Full Story

rustyj14

mikkyleOriginal Author

rcmoser

Greg Goyeneche

mikkyleOriginal Author

loger_gw