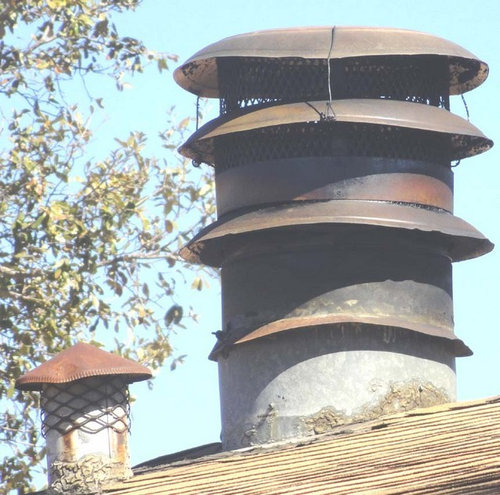

Cleaning our 6' deep fireplace chimney was a Flop

loger_gw

9 years ago

Related Stories

HOUSEKEEPINGBefore You Roast Those Chestnuts, Make Sure You've Got a Clean Chimney

Here's how to ensure your chimney is safe for holiday gatherings by the fire

Full Story

HOUSEKEEPING20 Things You Might Be Forgetting to Spring-Clean

Clean these often-neglected areas and your house will look and feel better

Full Story

REMODELING GUIDESClean-Burning Woodstoves Ignite a Greener Heating Trend

No need to rely on oil or gas to heat your home — new woodstove designs burn cleanly and are beautiful to boot

Full Story

HOUSEKEEPINGHow to Clean a Glass Shower Door

See which tools and methods will keep those glass shower walls and doors sparkling clean

Full Story

REMODELING GUIDES15 Ways to Design an Easy-Clean Home

Spend more time doing what you love with these pointers for minimizing cleaning needs throughout the entire house

Full Story

ORGANIZINGProfessional Tips for Organizing Your Clothes Closet

As summer draws to a close, get expert advice on editing and organizing your wardrobe

Full Story

HOUSEKEEPINGHow to Clean Marble Countertops and Tile

Acidic solutions can damage your marble surfaces. Here’s how to keep marble looking clean and amazing

Full Story

KITCHEN DESIGNDesign an Easy-Clean Kitchen

"You cook and I'll clean" might no longer be a fair trade with these ideas for low-maintenance kitchen countertops, cabinets and floors

Full Story

KITCHEN DESIGNKitchen of the Week: Brick, Wood and Clean White Lines

A family kitchen retains its original brick but adds an eat-in area and bright new cabinets

Full Story

MOST POPULAR33 Magic Household Cleaning Tips

Houzzers from around the world share their tips for transforming housework into child’s play

Full Story

loger_gwOriginal Author

ewalk

Related Professionals

Forest City Landscape Architects & Landscape Designers · Brandon Landscape Contractors · Flagstaff Landscape Contractors · Fort Mill Landscape Contractors · Lemoore Landscape Contractors · North Highlands Landscape Contractors · Smyrna Landscape Contractors · Southbury Landscape Contractors · Sun City Center Landscape Contractors · Palos Hills Landscape Contractors · Palos Heights Landscape Contractors · Haddonfield Decks, Patios & Outdoor Enclosures · Racine Decks, Patios & Outdoor Enclosures · Wentzville Decks, Patios & Outdoor Enclosures · West Chester Decks, Patios & Outdoor Enclosuresloger_gwOriginal Author

loger_gwOriginal Author

loger_gwOriginal Author