String trimmer won't idle...please help!

kentc80

13 years ago

Related Stories

FURNITURE12 Sofa Colors That Won't Box You In

With any of these colors as a base, you can change your decor as often as you change your mind

Full Story

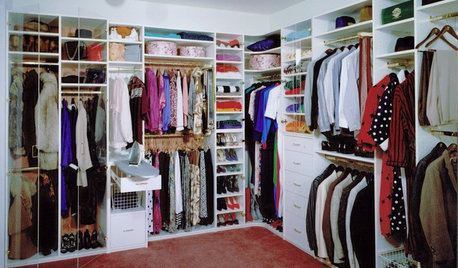

DECLUTTERINGDownsizing Help: How to Edit Your Belongings

Learn what to take and what to toss if you're moving to a smaller home

Full Story

ORGANIZINGDo It for the Kids! A Few Routines Help a Home Run More Smoothly

Not a Naturally Organized person? These tips can help you tackle the onslaught of papers, meals, laundry — and even help you find your keys

Full Story

PETS6 Ways to Help Your Dog and Landscape Play Nicely Together

Keep your prized plantings intact and your dog happy too, with this wisdom from an expert gardener and dog guardian

Full Story

DECLUTTERINGDownsizing Help: How to Get Rid of Your Extra Stuff

Sell, consign, donate? We walk you through the options so you can sail through scaling down

Full Story

LIFEHow to Handle Inherited Things You Don’t Really Want

Whether you’ve inherited a large collection of items or a single bulky piece of furniture, it’s OK to let it go if you don’t need or want it

Full Story

FUN HOUZZ10 Things People Really Don’t Want in Their Homes

No love lost over fluorescent lights? No shocker there. But some of these other hated items may surprise you

Full Story

FUN HOUZZDon’t Be a Stickybeak — and Other Home-Related Lingo From Abroad

Need to hire a contractor or buy a certain piece of furniture in the U.K. or Australia? Keep this guide at hand

Full Story

FURNITUREYour Essential Sofa Buying Guide

Here’s what to consider when looking for a quality sofa that will last

Full Story

PATTERN17 Gorgeous Ways to Work In a Patterned Area Rug

Add spark underfoot and pull a room together all around with a patterned rug as bold or subtle as you please

Full StoryMore Discussions

ewalk

kentc80Original Author

Related Professionals

Forest Park Landscape Architects & Landscape Designers · Pottstown Landscape Contractors · Wilmington Landscape Contractors · Fountain Valley Landscape Contractors · Gallatin Landscape Contractors · Melrose Park Landscape Contractors · Monterey Landscape Contractors · Reisterstown Landscape Contractors · Fort Worth Decks, Patios & Outdoor Enclosures · Lincoln Decks, Patios & Outdoor Enclosures · Meridian Decks, Patios & Outdoor Enclosures · South Houston Decks, Patios & Outdoor Enclosures · Westford Decks, Patios & Outdoor Enclosures · Highland Decks, Patios & Outdoor Enclosures · Newington Home Buildersewalk

masiman

ewalk

strelnikov

kentc80Original Author

masiman

ewalk

dlb014_aol_com

ewalk

MerlinG

the_0utsider