multiple failures with bump advance string trimmers

daver_g

15 years ago

Related Stories

MOST POPULAR8 Questions to Ask Yourself Before Meeting With Your Designer

Thinking in advance about how you use your space will get your first design consultation off to its best start

Full Story

LIGHTINGThe Lowdown on High-Efficiency LED Lighting

Learn about LED tapes, ropes, pucks and more to create a flexible and energy-efficient lighting design that looks great

Full Story

LIGHTING10 Ways to Get Your Lighting Right

Learn how to layer table lamps, floor lamps and overhead fixtures to get the lighting you need and the mood you want

Full Story

LIGHTINGWhat to Know About Switching to LED Lightbulbs

If you’ve been thinking about changing over to LEDs but aren't sure how to do it and which to buy, this story is for you

Full Story

CONTRACTOR TIPSWhat to Look for in a Contractor's Contract

10 basic ingredients for a contract will help pave the way to remodel happiness

Full Story

WORKING WITH PROSWhat Do Landscape Architects Do?

There are many misconceptions about what landscape architects do. Learn what they bring to a project

Full Story

GREAT HOME PROJECTSHow to Add a Radiant Heat System

Enjoy comfy, consistent temperatures and maybe even energy savings with hydronic heating and cooling

Full Story

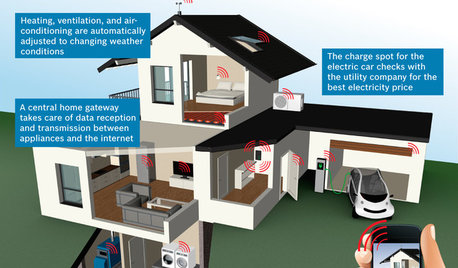

THE HARDWORKING HOMECES 2015: Inching Toward a Smarter Home

Companies are betting big on connected devices in 2015. Here’s a look at what’s to come

Full Story

WORKING WITH AN ARCHITECTWho Needs 3D Design? 5 Reasons You Do

Whether you're remodeling or building new, 3D renderings can help you save money and get exactly what you want on your home project

Full Story

fruitjarfla

zoomie46

Related Professionals

Panama City Landscape Architects & Landscape Designers · Annandale Landscape Contractors · Canyon Lake Landscape Contractors · La Mirada Landscape Contractors · Secaucus Landscape Contractors · View Park-Windsor Hills Landscape Contractors · Grafton Decks, Patios & Outdoor Enclosures · High Point Decks, Patios & Outdoor Enclosures · Lauderdale Lakes Decks, Patios & Outdoor Enclosures · Universal City Decks, Patios & Outdoor Enclosures · Broadlands Home Builders · Los Banos Home Builders · Pine Bluff Home Builders · Reedley Home Builders · Vista Park Home Buildersgator_rider2

montane1

rcmoser

goodhors

den69rs96

rcmoser

arkie62

green-zeus

booster

fruitjarfla

ccecilm

jarnkm

daver_gOriginal Author

lourash_myfairpoint_net

yungman

dontknow

paulflyboy

dontknow

canguy

musikman

glenam

sportlivin

gumby_ct

loger_gw

ron gralewski