compressor oil

stripped_threads

16 years ago

Related Stories

GARAGESHouzz Call: How Do You Put Your Garage to Work for Your Home?

Cars, storage, crafts, relaxing ... all of the above? Upload a photo of your garage and tell us how it performs as a workhorse

Full Story

MOST POPULAR5 Ways to Hide That Big Air Conditioner in Your Yard

Don’t sweat that boxy A/C unit. Here’s how to place it out of sight and out of mind

Full Story

LIFEHow to Prepare for and Live With a Power Outage

When electricity loss puts food, water and heat in jeopardy, don't be in the dark about how to stay as safe and comfortable as possible

Full Story

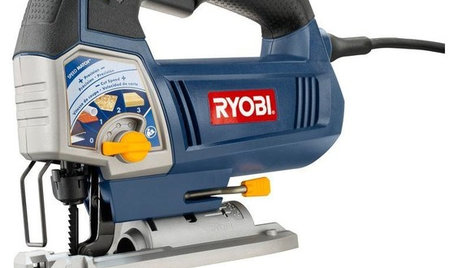

PRODUCT PICKSGuest Picks: Indispensable Tools for DIYers

Build your tool arsenal with these, and you’ll have the right equipment for any home project you take on

Full Story

HOUSEKEEPINGWhat's That Sound? 9 Home Noises and How to Fix Them

Bumps and thumps might be driving you crazy, but they also might mean big trouble. We give you the lowdown and which pro to call for help

Full Story

DECORATING GUIDES10 Ways to Hide That Air Conditioner

Feeling boxed in designing around your mini-split air conditioner? Try one of these clever disguises and distractions

Full Story

HOUSEKEEPING7-Day Plan: Get a Spotless, Beautifully Organized Garage

Stop fearing that dirty dumping ground and start using it as the streamlined garage you’ve been wanting

Full Story

MOVINGHome-Buying Checklist: 20 Things to Consider Beyond the Inspection

Quality of life is just as important as construction quality. Learn what to look for at open houses to ensure comfort in your new home

Full Story

REMODELING GUIDESGet the Look of a Built-in Fridge for Less

So you want a flush refrigerator but aren’t flush with funds. We’ve got just the workaround for you

Full Story

KITCHEN DESIGNShow Us Your Fabulous DIY Kitchen

Did you do a great job when you did it yourself? We want to see and hear about it

Full Story

canguy

green_valley

Related Professionals

Wareham Landscape Architects & Landscape Designers · Billerica Landscape Contractors · Buford Landscape Contractors · Boca Raton Landscape Contractors · Bowie Landscape Contractors · Dallas Landscape Contractors · Gloucester Landscape Contractors · Mission Bend Landscape Contractors · Shirley Landscape Contractors · Fairfax Decks, Patios & Outdoor Enclosures · Montgomery County Decks, Patios & Outdoor Enclosures · St. Louis Decks, Patios & Outdoor Enclosures · California Home Builders · Delano Home Builders · Duarte Home Builderscranheim

canguy

cranheim

green_valley

cranheim

picanoor

green_valley

den69rs96

broke_not

canguy