Mighty Mac Knife Replacement

garystpaul

10 years ago

Related Stories

KITCHEN STORAGEKnife Shopping and Storage: Advice From a Kitchen Pro

Get your kitchen holiday ready by choosing the right knives and storing them safely and efficiently

Full Story

KITCHEN STORAGE13 Popular Kitchen Storage Ideas and What They Cost

Corner drawers, appliance garages, platter storage and in-counter knife slots are a few details you may not want to leave out

Full Story

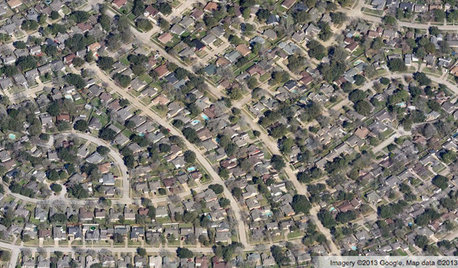

COMMUNITYGet a Bird's-Eye View of America's Housing Patterns

See the big picture of how suburban developments are changing the country's landscape, with aerial photos and ideas for the future

Full Story

ARCHITECTUREHouzz Tour: A Most Unusual Trailer in Texas

With an air-conditioned bathroom, screened porches and a sleeping loft, this riverside trailer site has it all

Full Story

PRODUCT PICKSGuest Picks: The Well-Stocked Starter Kitchen

We’ve got all the kitchen basics and tableware you need (or that recent grad needs) to make cooking a joy

Full Story

KITCHEN DESIGN10 Big Space-Saving Ideas for Small Kitchens

Feeling burned over a small cooking space? These features and strategies can help prevent kitchen meltdowns

Full Story

MATERIALSAre You a Maker? Show Us Your Favorite Tool or Material

Houzz Call: A tool or material can be a maker’s best friend. We’d like to see your favorite — and what it helps you achieve

Full Story

KITCHEN DESIGNCreate Your Own Checklist for a Well-Stocked Kitchen

Personalize the kitchen with your own must-haves from our list of top cooking tools, small appliances, pots, pans and more

Full Story

KITCHEN COUNTERTOPSKitchen Counters: High-Tech Solid Surfaces Make Maintenance Easy

Sculpted by heat and nonporous by nature, solid-surface countertops bring imagination and low maintenance to the kitchen

Full Story

ARCHITECTURE10 Advantages of the Humble Ranch House

Boomer-friendly and not so big, the common ranch adapts to modern tastes for open plans, outdoor living and midcentury mojo

Full StoryMore Discussions

tom_nwnj

garystpaulOriginal Author

Related Professionals

Eden Prairie Landscape Architects & Landscape Designers · North New Hyde Park Landscape Architects & Landscape Designers · Otsego Landscape Architects & Landscape Designers · Aloha Landscape Contractors · East Lake-Orient Park Landscape Contractors · Fort Myers Landscape Contractors · Fountain Valley Landscape Contractors · Hampton Bays Landscape Contractors · Ramsey Landscape Contractors · Los Alamitos Decks, Patios & Outdoor Enclosures · Prescott Decks, Patios & Outdoor Enclosures · Aliso Viejo Home Builders · Cypress Home Builders · Reedley Home Builders · Spanish Springs Home Builderstom_nwnj

zen_man

garystpaulOriginal Author

garystpaulOriginal Author

zen_man

garystpaulOriginal Author

zen_man

garystpaulOriginal Author