Breaking String Trimmer Line Excessively.

loger_gw

13 years ago

Related Stories

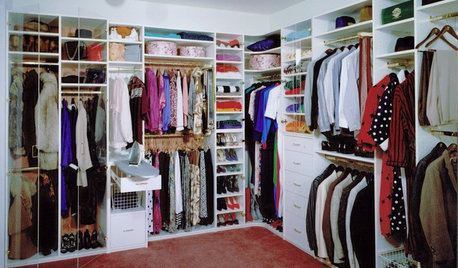

DECLUTTERINGDownsizing Help: How to Edit Your Belongings

Learn what to take and what to toss if you're moving to a smaller home

Full Story

LIFEThe Wisdom of Kenny Rogers, for Declutterers

No need to gamble on paring-down strategies when the country music legend has already dealt out some winning advice

Full Story

HOUSEKEEPING7-Day Plan: Get a Spotless, Beautifully Organized Garage

Stop fearing that dirty dumping ground and start using it as the streamlined garage you’ve been wanting

Full Story

HOUSEKEEPINGTo-Dos: Your July Home Checklist

Crank up the ice cream maker, hang up the hammock and raise the outdoor umbrella. Summer's in full swing this month

Full Story

MOVING9 Ways to Calm New-Home Jitters

Buyer's remorse begone! Here are some tricks to help you warm to your new place, warts and all

Full Story

FALL GARDENING5 Ways to Put Fall Leaves to Work in Your Garden

Improve your soil and yard the organic way with a valuable garden booster that grows on trees

Full Story

LIGHTINGWhat to Know About Switching to LED Lightbulbs

If you’ve been thinking about changing over to LEDs but aren't sure how to do it and which to buy, this story is for you

Full Story

GARDENING GUIDESNew Ways to Think About All That Mulch in the Garden

Before you go making a mountain out of a mulch hill, learn the facts about what your plants and soil really want

Full Story

LIFEYou Showed Us: 20 Nutty Home Fixes

We made the call for your Band-Aid solutions around the house, and you delivered. Here's how you are making what's broken work again

Full Story

LANDSCAPE DESIGNYour Mini Guide to Great Garden Edges

Get the scoop on trenches to the skinny on bender board, to help keep your garden beds as tidy as you like

Full Story

canguy

zoulas

Related Professionals

Canton Landscape Architects & Landscape Designers · Ashland Landscape Architects & Landscape Designers · Windham Landscape Architects & Landscape Designers · Garden City Landscape Architects & Landscape Designers · Sahuarita Landscape Architects & Landscape Designers · Edmond Landscape Contractors · Dinuba Landscape Contractors · Hollywood Landscape Contractors · Mequon Landscape Contractors · Wickliffe Landscape Contractors · Welby Decks, Patios & Outdoor Enclosures · Fort Collins Decks, Patios & Outdoor Enclosures · Miami Decks, Patios & Outdoor Enclosures · Mobile Decks, Patios & Outdoor Enclosures · Conroe Home Buildersloger_gwOriginal Author

exmar zone 7, SE Ohio

rcmoser

loger_gwOriginal Author

ewalk

Psycho0124

loger_gwOriginal Author

exmar zone 7, SE Ohio