Is replacing Troy-Bilt, Blade's Drive Belt a reasonable DIY job?

loger_gw

12 years ago

Related Stories

GREAT HOME PROJECTSHow to Replace or Revamp Your Garage Doors

Boost curb appeal and maybe even security with new garage doors. Find out cost ranges and other important details here

Full Story

BEFORE AND AFTERSSee a DIY Powder Room Transformation for $1,100

Determination, DIY skill and a stunning tile feature wall helped make this formerly dark and gloomy powder room feel spacious

Full Story

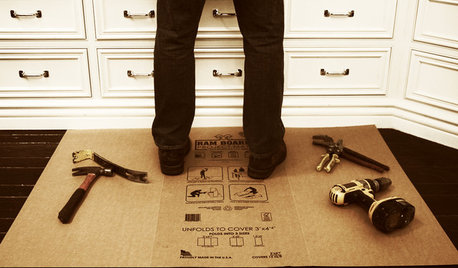

DIY PROJECTS14 Power Tools for the Home Shop

Want the thrill of building it yourself? These "big guns" help the handy homeowner tackle just about any job

Full Story

HOUSEKEEPINGWhat's That Sound? 9 Home Noises and How to Fix Them

Bumps and thumps might be driving you crazy, but they also might mean big trouble. We give you the lowdown and which pro to call for help

Full Story

KITCHEN SINKSEverything You Need to Know About Farmhouse Sinks

They’re charming, homey, durable, elegant, functional and nostalgic. Those are just a few of the reasons they’re so popular

Full Story

DIY PROJECTSThe Taming of the Screw

Learn the different types and uses of screws to pick the right kind for your next DIY or home improvement project

Full Story

BATHROOM DESIGNOut With the Old Tile: 8 Steps to Prep for Demolition

This isn't a light DIY project: You'll need heavy-duty tools and plenty of protection for your home and yourself

Full Story

LIFEStressed Out? Try Hitting the Woodshop

Building things with your hands just might boost your mood while giving you personal new pieces for your home

Full Story

GREEN BUILDINGHouzz Call: What Have You Salvaged for Home Use?

If your floors, furniture, exterior materials or other home elements have a past life, we'd like to hear the story

Full Story

HOUSEKEEPING20 Tools Every Homeowner Should Have

You probably have a hammer, but that's just a start. These 20 tools and devices are superstars for household projects and repairs

Full Story

javert

loger_gwOriginal Author

Related Professionals

Ballenger Creek Landscape Architects & Landscape Designers · Cedar Hill Landscape Contractors · Dunwoody Landscape Contractors · Emmaus Landscape Contractors · Lexington Landscape Contractors · Palatine Landscape Contractors · Uxbridge Landscape Contractors · Woodburn Landscape Contractors · Bowie Decks, Patios & Outdoor Enclosures · Draper Decks, Patios & Outdoor Enclosures · Green Bay Decks, Patios & Outdoor Enclosures · Lansdale Decks, Patios & Outdoor Enclosures · Lebanon Decks, Patios & Outdoor Enclosures · Pecan Grove Decks, Patios & Outdoor Enclosures · Homestead Home Buildersloger_gwOriginal Author

javert

loger_gwOriginal Author

javert

loger_gwOriginal Author