air compressor tank rusting craftsman 175 psi

davefrommd

16 years ago

Related Stories

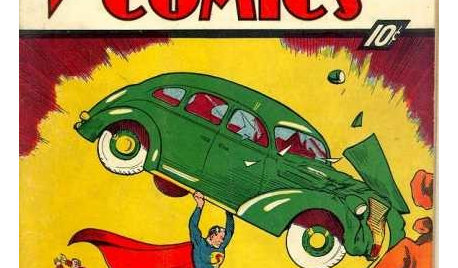

REMODELING GUIDESOne Guy Found a $175,000 Comic in His Wall. What Has Your Home Hidden?

Have you found a treasure, large or small, when remodeling your house? We want to see it!

Full Story

LIFEHouzz Call: Show Us Your Nutty Home Fixes

If you've masterminded a solution — silly or ingenious — to a home issue, we want to know

Full Story

MOST POPULAR19 Kitchen Projects Every Homeowner Should Know About

Could your kitchen use a new sink, a backsplash, updated hardware, better organization, a good cleaning? Here's how to get started

Full Story

mla2ofus

ladylake

Related Professionals

Ashland Landscape Architects & Landscape Designers · Panama City Landscape Architects & Landscape Designers · San Juan Landscape Architects & Landscape Designers · East Patchogue Landscape Architects & Landscape Designers · Williamsburg Landscape Contractors · Bridgeport Landscape Contractors · Ellicott City Landscape Contractors · Post Falls Landscape Contractors · Wallingford Landscape Contractors · Boston Decks, Patios & Outdoor Enclosures · Columbia Decks, Patios & Outdoor Enclosures · Huntington Decks, Patios & Outdoor Enclosures · Buena Park Home Builders · Fruit Heights Home Builders · Vista Park Home Builderslbpod

green_valley