Wood chipper clutch

woodchipnut

11 years ago

Related Stories

LIVING ROOMSHow to Convert Your Wood-Burning Fireplace

Learn about inserts and other options for switching your fireplace from wood to gas or electric

Full Story

KITCHEN DESIGNCool Countertops: Wood and Stainless

Consider One of These Alternatives to What All the Neighbors Have

Full Story

STUDIOS AND WORKSHOPSStudio Tour: New Life for Reclaimed Wood in Austin

See what inspires this Texas woodworker and how he stays organized in his workshop

Full Story

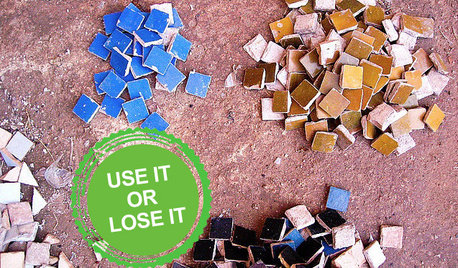

REMODELING GUIDESLose It: What to Do With Leftover Building Materials

See how to properly dispose of your extra brick, wood and paint — or make something cool with it instead

Full Story

GARDENING GUIDESMeet the Grass-Carrying Wasp, a Gentle Pollinator of Summer Flowers

These fascinating insects nest in wood cavities and hollow plant stems

Full Story

DECORATING GUIDESPhoto Murals Expand Reality

Freed from its tacky past, photographic wallpaper gives a whole new meaning to the term 'accent wall'

Full Story

WINDOW TREATMENTS9 Ideas for a Beautifully Draped Home

Go bold with your curtains and drapes for all the privacy you need and heightened drama too

Full Story

DECORATING GUIDESStroke of DIY Design Genius: 14 Crazy Cool Hand-Painted Walls

See how these homeowners used paintbrushes and permanent markers to create custom wallpaper

Full Story

DECORATING GUIDESPop Culture Watch: 12 Home Trends from the '80s Are Back

Hold on to your hat (over your humongous hair); interior design elements of the 1980s have shot forward to today, in updated fashion

Full Story

GARDENING GUIDESBackyard Birds: Northern Cardinals in the Snow, and Other Red Birds

Brilliant crimson feathers make these friends stand out in a crowd

Full Story

loger_gw

exmar zone 7, SE Ohio

Related Professionals

Comstock Park Landscape Architects & Landscape Designers · Braintree Landscape Contractors · Deerfield Beach Landscape Contractors · Lake Worth Landscape Contractors · Oxon Hill Landscape Contractors · Sun Valley Landscape Contractors · Golden Valley Landscape Contractors · Baltimore Decks, Patios & Outdoor Enclosures · Batavia Decks, Patios & Outdoor Enclosures · Hendersonville Decks, Patios & Outdoor Enclosures · Pittsburgh Decks, Patios & Outdoor Enclosures · St. Louis Decks, Patios & Outdoor Enclosures · Verona Decks, Patios & Outdoor Enclosures · Ellicott City Home Builders · Westmont Home BuildersGreg Goyeneche

robertz6

mark odeen