Chain saw - bar not getting oil

tom_nwnj

16 years ago

Featured Answer

Comments (11)

joecool85

16 years agomasiman

16 years agoRelated Professionals

Edmond Landscape Architects & Landscape Designers · Cary Landscape Architects & Landscape Designers · Dallas Landscape Contractors · Hilton Head Island Landscape Contractors · New Berlin Landscape Contractors · Palatine Landscape Contractors · Thornton Landscape Contractors · Wallingford Landscape Contractors · Huntington Decks, Patios & Outdoor Enclosures · Mobile Decks, Patios & Outdoor Enclosures · Ammon Home Builders · Centralia Home Builders · South Sioux City Home Builders · Vista Park Home Builders · West Jordan Home Buildersrcmoser

16 years agormh3481

16 years agodavidandkasie

16 years agorcmoser

16 years agopaddle

15 years agorcmoser

15 years agotom_nwnj

15 years agoddkalish_yahoo_com

13 years ago

Related Stories

MOST POPULARHow to Get Rid of Those Pesky Summer Fruit Flies

Learn what fruit flies are, how to prevent them and how to get rid of them in your home

Full Story

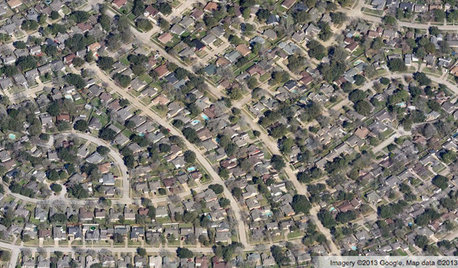

COMMUNITYGet a Bird's-Eye View of America's Housing Patterns

See the big picture of how suburban developments are changing the country's landscape, with aerial photos and ideas for the future

Full Story

HOUSEKEEPING7-Day Plan: Get a Spotless, Beautifully Organized Garage

Stop fearing that dirty dumping ground and start using it as the streamlined garage you’ve been wanting

Full Story

KITCHEN STORAGECabinets 101: How to Get the Storage You Want

Combine beauty and function in all of your cabinetry by keeping these basics in mind

Full Story

BATHROOM WORKBOOK12 Ways to Get a Luxe Bathroom Look for Less

Your budget bathroom can have a high-end feel with the right tile, stone, vanity and accessories

Full Story

LIFEThe Polite House: How Can I Kindly Get Party Guests to Use Coasters?

Here’s how to handle the age-old entertaining conundrum to protect your furniture — and friendships

Full Story

HOUSEKEEPINGHousekeeping 101: How to Clean Silver

Learn from a pro how to properly clean and care for your precious silverware

Full Story

LIFEGet the Family to Pitch In: A Mom’s Advice on Chores

Foster teamwork and a sense of ownership about housekeeping to lighten your load and even boost togetherness

Full Story

DECORATING GUIDES5 Decorating Tips for Getting Scale Right

Know how to work art, sectionals, coffee tables, lamps and headboards for a positively perfect interior

Full Story

SAVING WATERXeriscape Gardens: How to Get a Beautiful Landscape With Less Water

Conserve water and make gardening much easier with the xeriscape approach’s 7 principles

Full StorySponsored

Most Skilled Home Improvement Specialists in Franklin County

More Discussions

biglumber