Bigger engine on Mighty Mac

pawneepapa

11 years ago

Related Stories

SMALL SPACESHow Portability Can Make You Happier at Home

Downsizing your stuff and going for maximum mobility can actually make your home feel bigger and your life feel fuller

Full Story

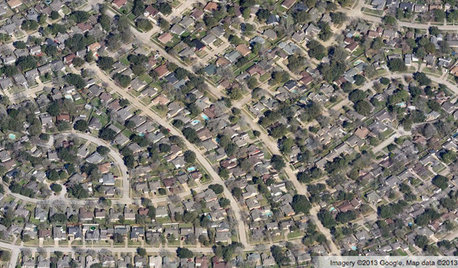

COMMUNITYGet a Bird's-Eye View of America's Housing Patterns

See the big picture of how suburban developments are changing the country's landscape, with aerial photos and ideas for the future

Full Story

CONTRACTOR TIPSBuilding Permits: 10 Critical Code Requirements for Every Project

In Part 3 of our series examining the building permit process, we highlight 10 code requirements you should never ignore

Full Story

WORKING WITH PROSHow to Hire the Right Architect: Comparing Fees

Learn common fee structures architects use and why you might choose one over another

Full Story

LIFEHouzz Call: Show Us Your Nutty Home Fixes

If you've masterminded a solution — silly or ingenious — to a home issue, we want to know

Full Story

KITCHEN DESIGN10 Big Space-Saving Ideas for Small Kitchens

Feeling burned over a small cooking space? These features and strategies can help prevent kitchen meltdowns

Full Story

OUTBUILDINGSThe Glass-Walled Cabin That Romance Built

Envisioning sunsets and starry skies, newlywed artists construct a 1-room retreat on a family farm

Full Story

KITCHEN DESIGNHouzz Call: Tell Us About Your First Kitchen

Great or godforsaken? Ragtag or refined? We want to hear about your younger self’s cooking space

Full Story

HOUSEKEEPINGHow to Tackle Your Home To-Dos

Make quick work of minor repairs and replacements with this thorough, step-by-step approach

Full Story

Houzz Call: Show Us Your Paint Makeovers

Let your newly repainted house or room do the "How d'ya like me now?" strut right here — it might just be featured in an upcoming ideabook

Full StoryMore Discussions

bill_kapaun

zen_man

Related Professionals

East Rancho Dominguez Landscape Architects & Landscape Designers · Garden City Landscape Architects & Landscape Designers · Glendora Landscape Architects & Landscape Designers · Parole Landscape Architects & Landscape Designers · Pottstown Landscape Contractors · Cicero Landscape Contractors · Doctor Phillips Landscape Contractors · Long Beach Landscape Contractors · Nutley Landscape Contractors · Oak Forest Landscape Contractors · Painesville Landscape Contractors · Rochester Landscape Contractors · Montgomery County Decks, Patios & Outdoor Enclosures · Reedley Home Builders · Westwood Home Buildersrunswithscissors2010

pawneepapaOriginal Author

mla2ofus

zen_man

pawneepapaOriginal Author

zen_man

pawneepapaOriginal Author

zen_man

shilohbounddoc

shilohbounddoc