Installing a fibreglass handle on a maul

dmullen

17 years ago

Related Stories

MATERIALSThe Most Popular Roofing Material is Affordable and Easy to Install

Asphalt shingles, the most widely used roof material in the U.S. are reliable and efficient, and may be right for you

Full Story

GREEN BUILDINGEcofriendly Cool: Insulate With Wool, Cork, Old Denim and More

Learn about the pros and cons of healthier alternatives to fiberglass and foam, and when to consider an insulation switch

Full Story

REMODELING GUIDESRenovation Detail: The Casement Window

If heaving open your windows leaves you winded, let the cranks or cam handles of casement windows bring in an easier breeze

Full Story

BATHROOM DESIGN18 Knockout Ideas for Wooden Floor Showers

Look to an often-forgotten material choice for shower floors that radiate beauty in almost any style bathroom

Full Story

GREEN BUILDINGInsulation Basics: Natural and Recycled Materials

Consider sheep’s wool, denim, cork, cellulose and more for an ecofriendly insulation choice

Full Story

GARDENING AND LANDSCAPING12 Naturally Beautiful Hot Tubs

Prefer a no-plastic look for your patio or yard? Wood, stone and concrete make these hot tubs fit right in with nature

Full Story

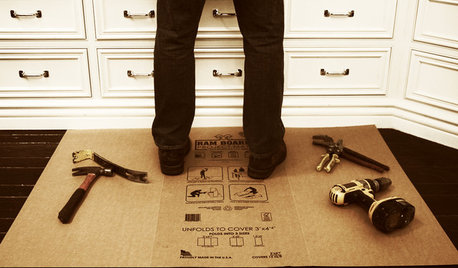

BATHROOM DESIGNOut With the Old Tile: 8 Steps to Prep for Demolition

This isn't a light DIY project: You'll need heavy-duty tools and plenty of protection for your home and yourself

Full Story

REMODELING GUIDESCool Your House (and Costs) With the Right Insulation

Insulation offers one of the best paybacks on your investment in your house. Here are some types to discuss with your contractor

Full Story

REMODELING GUIDESTop 10 Tips for Choosing Shower Tile

Slip resistance, curves and even the mineral content of your water all affect which tile is best for your shower

Full Story

MOST POPULAR8 Great Kitchen Cabinet Color Palettes

Make your kitchen uniquely yours with painted cabinetry. Here's how (and what) to paint them

Full StoryMore Discussions

rdaystrom

dmullenOriginal Author

Related Professionals

Piqua Landscape Architects & Landscape Designers · Buford Landscape Contractors · Hartford Landscape Contractors · Mooresville Landscape Contractors · Hilo Landscape Contractors · Lemont Landscape Contractors · Mission Landscape Contractors · New Berlin Landscape Contractors · New Braunfels Landscape Contractors · Secaucus Landscape Contractors · Crowley Landscape Contractors · Shenandoah Landscape Contractors · Centennial Decks, Patios & Outdoor Enclosures · Crestline Decks, Patios & Outdoor Enclosures · Rosemont Decks, Patios & Outdoor EnclosuresdmullenOriginal Author

montesa_vr

dmullenOriginal Author