stihl br600 blower

cranheim

12 years ago

Related Stories

CITY GUIDESTravel Guide: Kyoto, Japan, for Design Lovers

Experience ancient traditions and modern expressions in this design-minded roundup of sights, hotels, shops and restaurants

Full Story

KITCHEN DESIGNHow to Choose the Right Hood Fan for Your Kitchen

Keep your kitchen clean and your home's air fresh by understanding all the options for ventilating via a hood fan

Full Story

HOUSEKEEPINGIt’s Time to Clean Your Gutters — Here’s How

Follow these steps to care for your gutters so they can continue to protect your house

Full Story

KITCHEN APPLIANCESLove to Cook? You Need a Fan. Find the Right Kind for You

Don't send budget dollars up in smoke when you need new kitchen ventilation. Here are 9 top types to consider

Full Story

GREAT HOME PROJECTSHow to Give Your Driveway and Front Walk More Curb Appeal

Prevent injuries and tire damage while making a great first impression by replacing or repairing front paths

Full Story

MATERIALSInsulation Basics: What to Know About Spray Foam

Learn what exactly spray foam is, the pros and cons of using it and why you shouldn’t mess around with installation

Full Story

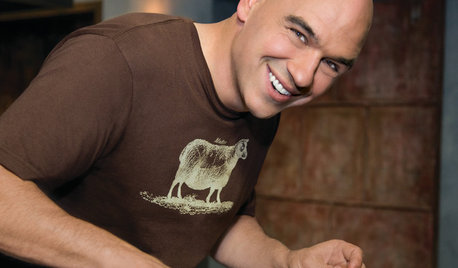

TASTEMAKERSPro Chefs Dish on Kitchens: Michael Symon Shares His Tastes

What does an Iron Chef go for in kitchen layout, appliances and lighting? Find out here

Full Story

LANDSCAPE DESIGNLandscaping Tricks to Manage Stormwater Runoff

Help rainwater absorb slowly back into the earth with paving grids, gravel beds and other porous systems

Full Story

FIREPLACESRibbons of Fire: 10 Artfully Minimalist Fireplaces

Long and lean and sleek to the core, these gas-burning fireplaces make a powerful contemporary statement

Full Story

KITCHEN DESIGN16 Practical Ideas to Borrow From Professional Kitchens

Restaurant kitchens are designed to function efficiently and safely. Why not adopt some of their tricks in your own home?

Full Story

ewalk

newjerseybt

Related Professionals

Erie Landscape Architects & Landscape Designers · Rossville Landscape Architects & Landscape Designers · Sahuarita Landscape Architects & Landscape Designers · Elgin Landscape Contractors · Kaysville Landscape Contractors · Lemay Landscape Contractors · Mequon Landscape Contractors · Mission Viejo Landscape Contractors · New Baltimore Landscape Contractors · Woodbury Landscape Contractors · Carlisle Decks, Patios & Outdoor Enclosures · Inwood Decks, Patios & Outdoor Enclosures · Leander Decks, Patios & Outdoor Enclosures · West Chicago Decks, Patios & Outdoor Enclosures · Clayton Home Builders