Tuff Torq K46 Tranny

I've been reading many of the posts on this site and there is varied opinion on the Tuff Torq K46 Tranny. Is it recommended that the fluid be changed every 100 hours or so and if "yes" how does one go about doing this. Also, what is better, conventional oil or synthetic?

I average about 50 hours/year - mainly just grass cutting, yard maintainance (dethatching, aerating, cart pulling, etc...) throughout the year and leaf clean-up in the fall. After reading a bunch of these posts I'm wondering if I should have bought an Army surplus tank or the like.

Your suggestions are appreciated.

Comments (80)

doberman_2007

14 years agoMY LX-76 I believe had a TUFF-TORQ tranny seviced it every 5 years light service, synthetic 10w-30 oil sold it an it runs great . My X534 has a k-72 in it, I believe and it is a bear. If you service it regularly it will treat you well ,,, unfortunately nothing is perfect.

tuco

Original Author14 years agoThought I'd post a follow-up after over a year and some months.

My '06 Craftsman YS4500 with the K46 tranny really started to get loud and I noticed it was beginning to slow down. I have some hilly areas and I think that pulling my loaded yard cart, weighted aerator, etc... on my 1.5 acre property began to take its toll. I believe this was beyond the engineered limits of this machine and would have eventually led to a premature death in the form of a tranny failure.

I'm not slamming any particular product here and am just reporting what I experienced. The tractor was a great lawn cutter and would have probably worked well for a long time on a flat property. I actually sold it for about $ 300.00 less than what I paid for it new, although I did add a few bells & whistles - wheel weights, steering wheel spinner, front bumper and a mulch kit w/gator blades.

I sold it after purchasing a used 2002 Toro Wheel Horse 522xi garden tractor. This is the right tractor for me and my property needs and should hopefully last for many years to come.

Related Professionals

Palm Springs Landscape Architects & Landscape Designers · Winder Landscape Architects & Landscape Designers · Cambridge Landscape Contractors · Hampton Bays Landscape Contractors · Homewood Landscape Contractors · Hoover Landscape Contractors · Matteson Landscape Contractors · Ridgewood Landscape Contractors · Saint Paul Landscape Contractors · Smyrna Landscape Contractors · Merrifield Landscape Contractors · Marietta Window Contractors · Enumclaw Window Contractors · San Juan Capistrano Window Contractors · Snoqualmie Window Contractorsbchamberlin

14 years agoUgh! I too have the k46 tranny in my l120 JD and am having all kinds of problems. After an hour going up a hill is nearly impossible. Don't have the cash for a new mower so I'm going to try replacing the tranny fluid. I assume since it's not serviceable you have to take off the pan/box. How do you fill it back up and what kind of tranny fluid do you use?

TedBell

14 years agoAfter reading this long thread I'm counting my blessings that my CC 2550 has a Hydrogear tranny!

kdoug

14 years agoThis has nothing to do with Hydrogear vs Tuff Torque. These are entry level transmissions on entry level lawn tractors. Similar to what comes in the CC 1000 series. In terms of reliability, the Tuff Torque K61, K66 and K72 are unmatched.

swashbuckler

14 years agoWhen changing the oil in the K46 they recomend 5W50 synthetic oil now. If you can't find it in a store nearby you can order it from the Tuff Torq corporation site.

Go to the Tuff Torq corporation site.swashbuckler

14 years agoI was having a lot of trouble with my lawn tractor losing power. I decided to find out why. After doing a little searching on the internet I found that I needed to change the oil in it. When I pulled out the sealer cap and the removed the magnet I found gritty sludge stuck to the magnet. I decided to take my transmission apart and clean it out real good. Everything went well untill I started to put it back together. The hydraulic pumps inside are a devil to reasemble. Especialy the one driven by the pully shaft on top of the tranny.

I found out also that it has TWO magnets and a small filter inside. The filter was really dirty.

There are two small steel balls inside that are really easy to lose. If anyone takes they'rs apart like I did be very carefull not to lose them.

I got my tranny all put back together now and am waiting for a new sealer cap and vent. I had to order those.

I am writing this to let folks know that sometimes just changine the oil may not be enough. You might have to do what I did and give it a good cleaning out. Especialy that fiber filter. It gets full of grit and sludge. I don't recomend disasembling the pump housing at all. I lost one of the tiny steel balls. Lucky for me I had another one.

The upper rotary pump (the one driven by the pully shaft ) is very hard to reasemble. I went to the Tuff Torq site and they recomend 5W50 synthetic oil in place of the 10W30 now. I had to order that too.

Best of luck with all your endeavers.greenymower

13 years agoIs it possible, or should I say practical, to drill the bottom of a K46 and install a drain plug? I assume the case would have to be disassembled to remove any metal shavings from drilling. It seems I read somewhere that on many mowers you have to remove the tranny to get to the fill cap. If that's true there probably isn't much point in a drain plug.

mamodbasher

13 years agoHello, I am new to the forum, so please bear with me. This January I bought a John Deere X300 with all of the toys - 44" snowblower, weights, chains, mulching kit, full winter cab and bra. It's a great tractor, but I was possibly misled as to its ability to do yard work, as it has (according to the JD specs) a k46 transmission. Having said that, I went to the Tuff Torq site and looked at the specs for the k46. According to Tuff Torq, the axles on the k46 are 3/4" diameter. When I measured the axles on my X300 using a micrometer, they are exactly 1" diameter. When I then checked the Tuff Torq site again, the first transmission that they list as having 1" axles is the k58. Even the k57 has 3/4" axles. I sent am email to the Tuff Torq people to see if they can advise, but if anyone here knows, feel free to jump in. I want to be able to use a Brinly 10" moldboard plow and possibly a disk-harrow. If it has a k58, then it might be OK, but if not? If all this tractor is good for is cutting grass and blowing snow, I could have bought the L-100 series and saved about $2K. Thanks for any input you may have - Ken.

metal

13 years agomamod, sounds like you needed a Garden Tractor and bought a Lawn Tractor. Did you tell the dealer you wanted to use ground engaging equipment when you bought it? I can't believe they would have recommended the X300 if they knew that.

mamodbasher

13 years agoHi metal - seems that I may not have made myself completely clear to the dealer. That being said, I can't understand JD making a tractor (let's say the LA-135SE) for $2000, then making the X300 for another $1000 more, when it has the same transmission in it? Heavier frame and steering components, etc., but still just a lawn mower that does exactly what an LA-135 does - makes no sense. Then, as I had said in my post, the axles are 1" and the k46 according to Tuff Torq are only 3/4". This leads me to believe that the X300 may have a more robust transmission, which might work out if that's the case. I am losing my faith in John Deere. The more I read about them, the more I wish I hadn't bought one. Too many models, too many variables and in the end, a ton of money for something to cut grass and not a whole lot more. I was also considering putting an additional electric cooling fan (12 volt unit) on the transmission to make sure that it gets a lot of air while in use. This can be disabled in winter when it's not needed. Ken.

freddyfast9

13 years agoIf you change the fluid in a non-servicable tranny like the K46 or K58 your warranty is gone as in bye bye. The techs can test to see if there is a different fluid type than it came with or they can tell if the amount of fluid has changed. I would feel better changing my fluid too but I would wait until the machine in question is out of warranty to do so or have the dealership do it.

pogo5a_aol_com

13 years agoi use my 16 hp regent w/ a k46 tranny to blow snow in the winter also and just a week ago i got stock spun the wheeles a lot then we got it out but later that morning it started to go slower called simplicity and they said to replace the drive belt no change it would run for about an hour then loose almost all power to move. any answers?

rcbe

13 years agoCramer -

prolly best to start a new thread - this one is old and long. Yer apt to get more/better replies that way.

M/W, chk your tranny fluid level per yer manual - also "smell" it for signs of overheated oil. Change oil/filter per manual if so.User

13 years agoPaul,

More likely than not you burned the oil in the transaxle and the only thing you can do is R&R the transaxle, replace the oil, and hope that solves the problem. If not, then a new transaxle is in your future.

The K46 takes 2.3 liters of 5w50 Synthetic Motor Oil or 10w30 API Class Motor Oil. The 5w50 synthetic is better.

When you blow snow does your Regent have chains and weights?

pogo5a_aol_com

13 years agoYes i have both chains and weights. how do I cahnge the oil and re fill no drain plug?

leafeanator

13 years agoThe X300 has a 3/4 inch axle, my 2010 model. Yes measuring the axle between the trans and wheel measures 1 inch, but that is a sleeve over the axle. Remove the plastic cap on the outside of the wheel- there it measures 3/4 inch.

slatskars_comcast_net

12 years agoI have a JD L-118 that has the loss of power when hot problem. A previous mower (Murray) had a Dana-Spicer transaxle with the hydro unit attached to it by a couple of bolts and driven by socket drive. The hydro unit could be removed and replaced without completely disassembling the transaxle. A much better idea. I used that mower for many years with no problems from the hydro unit. Other problems with the mower, but not the hydro drive.

jdicus_embarqmail_com

12 years agoI have a Husqvarna YTH2042 with a K-46 tranny. After 200hrs over 4 yrs and a lot of research I decided to change the transaxle oil. Contacted Tuff Torq engineering and they told me the USA and Canada are probably the only countries that don't order the option of two drain plugs in the bottom case. They e-mailed a detailed drawing indicating the two bosses where the drain plug holes are located. I pulled the tranny, drilled the holes,flushed the tranny a coup[le of times with cheap oil and filled it with 5W-50 synthetic oil and installed the two drain bolts supplied by Tuff Torq. Did this last summer and it's still working great. BTW- The engineer said this was about a 50 cent option.

User

12 years agoI'm in complete agreement that drain plugs should be a no brainer... now, the most likely reasons there are no drain plugs in the US...

$.50 x 1000,000 = we'd rather not spend the money

End users could-would forget to refill the tranny resulting in warranty claims and ill will.

We want to sell you another lawn tractor in 3 years.

jdicus_embarqmail_com

12 years agojustalurker...You are probably right on the reasons for omitting the drain plugs. I would think Tuff Torq would not option these items and put them on all trannys. They are taking a hit on their quality reputation. Seems it would be better to put them in and if the tractor manufacturer wanted to claim them as unserviceable the liability would be on their heads. Are you listening Tuff Torq???

User

12 years agoHaving been involved in decisions of this type and at that level I can tell you that marketing and product liability people have more weight in this kind of discussion than engineering people and the component manufacturer has no vote at all. TT listens to the OEM and reads the contract put in front of them.

The end user needs to punish the manufacturer for not listening not blame or criticize the component manufacturer who will happily provide whatever the OEM desires. Want drain plugs? Then vote with your wallet... simple as that.

brehm4_yahoo_com

12 years agoI blew a rear axle shaft seal on my Ariens Riding Mower. Needles to say it made a mess. I did replace the seal and filled the engine with W10-30 oil. The dipstick shows OK, but how do I fill the Trans Axle? It makes some noise. I think it is empty.

Thanks, Hans G Brehmkipsy

12 years agoyou have to take tranny out of tractor, turn upside down and drain oil thru fill plug, then reinstall and refill with the amount that came out.

Wood-man

12 years agoJust FYI,

I have a tuff torque K46 in my John Deere L118.

As described, my transmission was slipping big time and could not even make it up the slightest grade. I dropped the transmission out and open the vent cap and drained out all the oil. I then replaced it with two quarts of moble full synthetic 10w-30 . The transmission now works better than when it was new and will climb any hill with ease, with no slipping or that loud whinning noise. This web site just save me thousands....between replacing the transmission, $1000, or a new tractor, $3500!!!!!!Thanks for the post !

Silver-Wolf

12 years agoThe life of a hydrostatic transmission will be determined by heat,fluid level and the life of seals and gaskets. There is very little wear on the internal parts of the transmission (less the rear end)Breakdown of the oil from heat and low level of oil will kill the transmission. Once their is slipping when it get hot, the damage is done and will just get worse. If you cannot hold your hand on the transmission when it is hot, its too hot.

A Sundstrand/Hydrogear and Tuff Torq can be repaired, but dealers only replace the units. Have a hydraulic shop lap the cylinder blocks/thrust plates and valve block and its good as new. They only take about a few thousands of an inch off the surfaces and make they smooth again without any grooves in them. These parts can be lapped by owner using a smooth flat glass or flat granite plate, 320 to 600 grit wet/dry sandpaper and mineral spirits. Rotate the parts on the paper in a figure 8, while holding them down and flat. You should be able to get the grooves and scuff marks off. Wash these parts and make sure they are very clean and reinstall with oil on all the critical surfaces. Keep everything clean, it is everything.

[Hydro-Gear 310-0510 Transaxle] Cub Cadet Part# 618-0319

http://www.outdoordistributors.com/pdf/HYDRO-GEAR/BLN-51260_P1.pdf

http://www.outdoordistributors.com/Hydrogear/Hydrogear_Search.html Berendson Fluid Power for partsTuff-Torq

www.tufftorqservices.com/Joe53

10 years agodo any of you know if I can replace an axle seal on an LA175 without pulling the K46 apart?

sure would be nice if I could do that.

thks

User

10 years agoJoe,

You'll get your answer when you start a new thread with your question rather than hijack a 5 year old thread.

dleebold

10 years agoi did the siphon hose from the filler hole removal method.filled trans with 5-40 mobile one synthetic.think i'll refill every 200 hrs as others have advised.

leafeanator

10 years agoI pulled the K46 from my X300 a couple years ago at 50 hours and drained and replaced the oil with 5W-50 synthetic. Took a total of about 1 hour. Got rid of the cheap factory oil JD asks for. It's been running fine, now at 175 hours. Keep it clean and cool. For FULL information on servicing the K46 search for "TuffTorq K46 Repair Guide with Pictures" on the internet.

Here is a link that might be useful: K46 repair guide

badgolfermike

9 years agoThanks to everyone for the information above, it helped me to breathe some life back into my 19 year old JD Sabre 1646. It wouldn't hardly move in reverse when hot (I changed the fluid last season 10w30 conventional per manual for the same reason). I was lucky enough to have drain plugs, so I thought that I might as well experiment a little. After draining the tranny overnight, I refilled it with Mobile 1 15w50 synthetic. The hydro behaves like new (better?), with no fading even after 65 minutes of mowing. I don't use it at all when cold out so l thought the 15 base weight was worth a shot.

This post was edited by badgolfermike on Wed, Jun 4, 14 at 20:13

stillhere

9 years agoMy 7 year old Craftsman YS4500 slowed to a crawl, especially in turns.

Found this forum and received some good info, particularity from "Mowie".Pulled the K46, drained the fluid. It was darkish gray in color. Replaced with two quarts SAE Non detergent 30w that I bought from Autozone. Cleaned it good and re-installed. It works better than ever.

A couple of hours on the garage floor, $8.00 worth of oil and replacing my wife's glass measuring bowl -vs- several hundreds of dollars to repart/repair/replace!!!

I hope everyone finds this forum as useful as I have.

Happy Mowing & Stillhere.byronmill

9 years agoNote to those of you commenting on these posts about putting a drain plug in the transaxle and also those describing draining the transmission by siphoning the oil out of the fill plug.

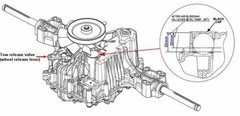

This transaxle has 2 completely separate chambers in it that both contain oil. One side has the drive gears (the side with the big "bump" out on the bottom pan) and the other side has the hydro pump and motor. The two side are only connected by the fill port area where the magnet sets into.

If you do wish to install a drain plug in the bottom pan you will need to put one in each side to drain both chambers.

In a similar fashion, if you are going to siphon out oil to change it you will have to get your siphon tube inserted into both the fill openings under the fill cap.

Just pull the transaxle and invert it to drain. DO NOT try to pull out the vent, you will break it. Fill cap is under the fan/pulley which has to be removed to access the cap and drain.

While the transaxle is out it is a good time to clean it up and inspect it.

leafeanator

9 years agoFor installing drain ports see Tuff Torq site below

Here is a link that might be useful: K46 drain ports

jgormansr

9 years agoI have a K46BT on my Craftsman 54" Lawn tractor. I noticed over the last few years that the speed in reverse got slower and slower. Now it barely moves at all. Forward works good. Any sugestions? I see that there is no drain for fluid...is there a fill cap? Thanks for any info in advance.

urbanbrewhaha

7 years agoThanks to this Thread I was able to repair the LT180 I just bought at an auction. All was good until about 30 minutes of mowing when the world stopped turning and the machine was barely moving. After reading all the info above I took a slightly different approach to remedy the slow trans-axle condition. Taking the least aggressive path, I was curious if just a fluid change would make a difference, I decided to jack the rear end up and pop a couple drain holes into the Axle cast housing where Tuff-Torq suggests. Here is a Link

I used a 1/8 stubby drill as not to injure any interior components, both holes drained over night. I then added 2 self tapping screws 1/2 inch long with a neoprene washer.

Without the deck on the machine I was able to reach under the frame and pop the fill hole cover off using a stubby flat screwdriver. I cleaned up the magnet and filled the unit. 24 inches of 3/8 clear tubing and a small funnel allowed me to add back the 2 quarts of cheap 10-30 oil for my test. Popped the magnet and cap back in place and DONE!

I am pleased that the result was success, the machine runs very well without growling and slowing after 30 minutes of use.

My intention is to replace the 2 small drain holes with real drain plugs after about 5 hours of use and refill the unit with synthetic oil for hopefully many more years of use. Happy Mowing!!

leafeanator

7 years agoUsually if the trans is slow an oil change only does not help much, done more for preventive maintenance . Glad yours did. Boy an 1/8 hole probably drained real slow:) What color was the drained oil?

urbanbrewhaha

7 years agoThe oil was asphalt black with a silver tint, no doubt many years of use, the unit has 705 hours on it. The two 1/8" holes took about 30 minutes to drain before slowing to a drip, then I just left it drip overnight. Since this was an auction buy I am hesitant to invest too much into it until I know the rest of the machine is solid, I am hoping the fluid change will at least allow me to evaluate it under real use. At some point I can see a full rebuild for the K46 if the unit is worthy, fingers crossed.

rexlex

7 years agoleafonator - i'm puzzled. what data provided your assessment that tranny oil change is not usually helpful?

leafeanator

7 years agoIt is not useful if the internal parts are worn, scratched and leaking which requires a rebuild. Oil change is preventative to put in clean oil and remove dirty oil that has contaminates like carbon particles from overheating. Same as changing oil in your car. I changed mine at 50 hours and again at 150 hours and at 150 it felt like the change did give a LITTLE more pep - surprised me as the old oil didn't look too bad. If you checkout the "K46 repair guide with pictures" very few report good results with an oil change if the tranny is really bad.

Always worth a try if the tranny is not up to par, it's cheap.

wheely_boy

7 years agoI think someone is looking for some data; spread sheets, graphs, that sort of stuff.

rexlex

7 years agowhy rollergirl yer simply amazing with your depth. never woulda guessed you for a numbers nerd....

massiveoverkill

7 years agoAfter reading the horror stories of K46's going out I replaced my fluid after a 20 hour break-in with Mobile 1 racing synthetic. Using any synthetic is better than conventional but why use conventional synthetic, which is made to satisfy emissions standards? It's not going in your crankcase. Use a racing synthetic that has high zinc and phosphorous content and the formulation isn't compromised to save catalytic converters which you don't care about for this application. I use a snow blade attachment and my transmission works better than when it was new, especially in colder weather. Those of you going through the trouble of swapping out your oil, I don't know why you would go through all that trouble and then replace it with conventional oil. Tuff Torque even recommends synthetic. Hopefully I'll be able to come back here in 5-6 years and say my transmission is still going strong.

wrager