Inflating utility cart tires

dynamike59

14 years ago

Related Stories

GREAT HOME PROJECTSHow to Make Your Garage a Storage Powerhouse

New project for a new year: Add shelving and containers to get your stuff off the garage floor — and still have room for the car

Full Story

HOUSEKEEPING7-Day Plan: Get a Spotless, Beautifully Organized Garage

Stop fearing that dirty dumping ground and start using it as the streamlined garage you’ve been wanting

Full Story

HOUZZ TOURS13 Character-Filled Homes Between 1,000 and 1,500 Square Feet

See how homeowners have channeled their creativity into homes that are bright, inviting and one of a kind

Full Story

LIFE10 Reasons to Be Happy You’re a Renter

Homeownership has many benefits, but there are upsides to not owning a home too

Full Story

SMALL SPACESDownsizing Help: Where to Put Your Overnight Guests

Lack of space needn’t mean lack of visitors, thanks to sleep sofas, trundle beds and imaginative sleeping options

Full Story

SHOP HOUZZHouzz Products: Great Gifts for Dad

Father’s Day is June 15! Make Dad feel like the king of his castle with one of these gifts from the Houzz Products section

Full Story

LAUNDRY ROOMSTop 10 Trending Laundry Room Ideas on Houzz

Of all the laundry room photos uploaded to Houzz so far in 2016, these are the most popular. See why

Full Story

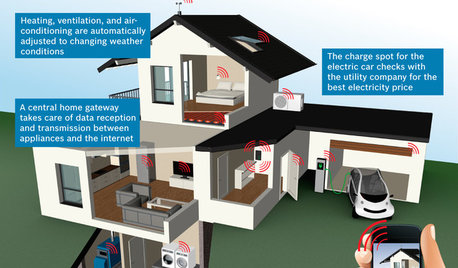

THE HARDWORKING HOMECES 2015: Inching Toward a Smarter Home

Companies are betting big on connected devices in 2015. Here’s a look at what’s to come

Full Story

GARAGESHouzz Call: How Do You Put Your Garage to Work for Your Home?

Cars, storage, crafts, relaxing ... all of the above? Upload a photo of your garage and tell us how it performs as a workhorse

Full Story

SMALL KITCHENS10 Things You Didn't Think Would Fit in a Small Kitchen

Don't assume you have to do without those windows, that island, a home office space, your prized collections or an eat-in nook

Full StoryMore Discussions

runny214

rdaystrom

Related Professionals

Owings Mills Landscape Architects & Landscape Designers · Salem Landscape Contractors · Azalea Park Landscape Contractors · Eagle Landscape Contractors · Golden Gate Landscape Contractors · Hilton Head Island Landscape Contractors · Lancaster Landscape Contractors · Lebanon Landscape Contractors · Mastic Beach Landscape Contractors · New Baltimore Landscape Contractors · River Ridge Landscape Contractors · Wanaque Landscape Contractors · West Haverstraw Landscape Contractors · San Pablo Landscape Contractors · Calabasas Window Contractorsbaymee

rustyj14

wheelhorse_of_course

dynamike59Original Author

baymee

rdaystrom

wheely_boy

rdaystrom

net_worker

baymee

mownie

ewalk

rdaystrom

ewalk

hbrmstr

tedintexas

danihilist

wheely_boy

grass1950

User

enigma_2

User

Khristov12

rcbe

mownie