LA175 John Deere transaxle seal is leaking

Joe53

10 years ago

Related Stories

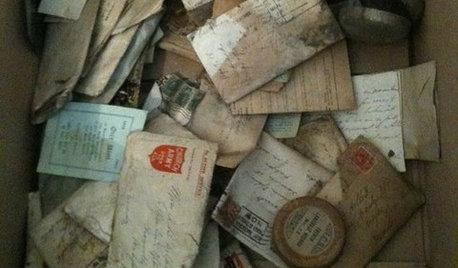

REMODELING GUIDESYou Won't Believe What These Homeowners Found in Their Walls

From the banal to the downright bizarre, these uncovered artifacts may get you wondering what may be hidden in your own home

Full Story

LIFEHow to Outsmart Backyard Critters

Learn to think like a raccoon, skunk or squirrel to keep your home safe and your garden intact

Full Story

BATHROOM DESIGN14 Design Tips to Know Before Remodeling Your Bathroom

Learn a few tried and true design tricks to prevent headaches during your next bathroom project

Full Story

MOST POPULAR10 Smart Ideas for Your Laundry Room Remodel

Make washing and drying easier and more comfortable by considering ergonomics, storage and special features

Full Story

BATHROOM DESIGN9 Surprising Considerations for a Bathroom Remodel

Don't even pick up a paint chip before you take these bathroom remodel aspects into account

Full Story

GARDENING AND LANDSCAPINGWhy Is There a Bathtub in the Backyard?

Nope, it's not waiting for bulk trash pickup. These days outdoor tubs are serving soakers, beer drinkers and even the fishes

Full Story

GREAT HOME PROJECTSHow to Make Your Garage a Storage Powerhouse

New project for a new year: Add shelving and containers to get your stuff off the garage floor — and still have room for the car

Full Story

KITCHEN DESIGN15 Farmhouse Kitchens That Made Us Swoon This Month

Raw wood, natural light, shiplap siding — we just couldn’t get enough of these farmhouse-style kitchens uploaded to Houzz in January

Full Story

LIFEShare Your Winter Storm Jonas Photos and Survival Tips!

Let’s see your pictures and hear your ideas on how you’re keeping your house warm and staving off cabin fever

Full Story

CONTRACTOR TIPSBuilding Permits: When a Permit Is Required and When It's Not

In this article, the first in a series exploring permit processes and requirements, learn why and when you might need one

Full Story

User

Joe53Original Author

Related Professionals

Fillmore Landscape Architects & Landscape Designers · Wheeling Landscape Architects & Landscape Designers · Jackson Landscape Contractors · Williamsburg Landscape Contractors · New Berlin Landscape Contractors · Seven Hills Landscape Contractors · Stony Brook Landscape Contractors · Watertown Landscape Contractors · Four Corners Landscape Contractors · Golden Valley Landscape Contractors · Vadnais Heights Landscape Contractors · Tucson Window Contractors · Arroyo Grande Window Contractors · Cicero Window Contractors · Two Rivers Window ContractorsUser

Joe53Original Author

User