tractor won't start - bad starter?

fcarp63

13 years ago

Related Stories

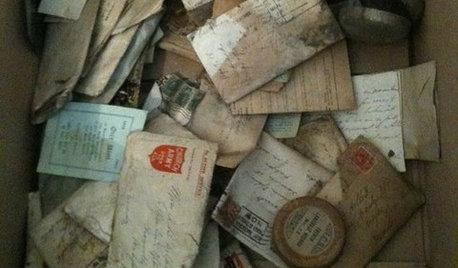

REMODELING GUIDESYou Won't Believe What These Homeowners Found in Their Walls

From the banal to the downright bizarre, these uncovered artifacts may get you wondering what may be hidden in your own home

Full Story

HOME TECH3 Kitchen Contraptions You Won’t Believe

Pizza hot from the printer, anyone? These cooking gadgets harness imagination and high tech — and have price tags to match

Full Story

LIFEYou Said It: ‘Put It Back’ If It Won’t Help Your House, and More Wisdom

Highlights from the week include stopping clutter from getting past the door, fall planting ideas and a grandfather’s gift of love

Full Story

GARDENING GUIDESHow to Stop Worrying and Start Loving Clay Soil

Clay has many more benefits than you might imagine

Full Story

PRODUCT PICKSGuest Picks: The Well-Stocked Starter Kitchen

We’ve got all the kitchen basics and tableware you need (or that recent grad needs) to make cooking a joy

Full Story

MOST POPULARHow to Start a Cool-Season Vegetable Garden

Late summer and late winter are good times to plan and plant cool-season crops like salad greens, spinach, beets, carrots and peas

Full Story

GARDENING FOR BUTTERFLIESA Quick-Start Guide to Bird-Watching for Fun and Learning

Set out some seed and grab your field guide. Bird-watching is an easy, entertaining and educational activity for the whole family

Full Story

ENTRYWAYSOrganizing Starts at the Door

You don't need fancy bins and containers to keep your entryway tidy — just a system that sticks

Full Story

BEDROOMSGet More From Your Bed (Storage, for Starters)

Find space for all your stuff — and maybe even a seat, a writing desk or another sleep spot — by cozying up to a multipurpose bed

Full Story

ARCHITECTUREDesign Practice: How to Start Your Architecture Business

Pro to pro: Get your architecture or design practice out of your daydreams and into reality with these initial moves

Full Story

mownie

pet575

Related Professionals

Ballenger Creek Landscape Architects & Landscape Designers · Glassmanor Landscape Architects & Landscape Designers · Woodinville Landscape Architects & Landscape Designers · Coeur d'Alene Landscape Contractors · Kearny Landscape Contractors · Lantana Landscape Contractors · Ponte Vedra Beach Landscape Contractors · Tigard Landscape Contractors · Wheat Ridge Landscape Contractors · Wichita Window Contractors · Madison Window Contractors · Revere Window Contractors · Sugarland Run Window Contractors · University City Window Contractors · Verona Window Contractorsmownie

rcmoser

pet575

mownie

pet575

fcarp63Original Author

rcmoser

mownie

fcarp63Original Author

fcarp63Original Author

mownie

fcarp63Original Author

rustyj14

mownie

mownie

rcmoser

fcarp63Original Author

mownie

farmallguy

mownie

farmallguy

mownie