Snapper rider wont move in 1st or 2ed gear!

rooster101

14 years ago

Related Stories

LIFERelocating? Here’s How to Make Moving In a Breeze

Moving guide, Part 2: Helpful tips for unpacking, organizing and setting up your new home

Full Story

ENTERTAININGModern Manners: Smooth Moves for Kids' Visits

For hosting kids or visiting with Junior in tow, we give you a plan to keep stress levels low and fun levels high

Full Story

KITCHEN DESIGNDisplaying Kitchen Supplies — Hot or Not?

Do some kitchens just beg for a cozy row of canisters and gear for all to see? Have a look and let us know what you think

Full Story

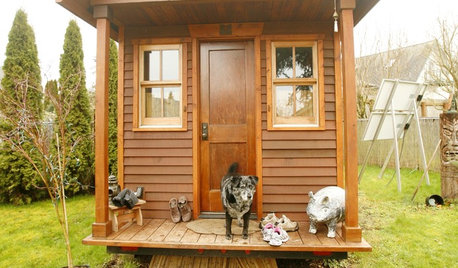

SMALL SPACESLife Lessons From 10 Years of Living in 84 Square Feet

Dee Williams was looking for a richer life. She found it by moving into a very tiny house

Full Story

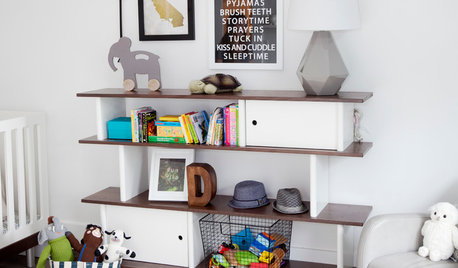

KIDS’ SPACES15 Tips for Small-Space Living With Baby

Keep your wee one's stuff under control and your nerves unfrazzled with these space-saving storage and baby-gear ideas

Full Story

PRODUCT PICKSGuest Picks: Handy Finds for Painting Projects of All Kinds

Make over rooms and furniture more easily and with better results with the right paint and gear

Full Story

MOVINGHow to Avoid Paying Too Much for a House

Use the power of comps to gauge a home’s affordability and submit the right bid

Full Story

LIFE10 Reasons to Be Happy You’re a Renter

Homeownership has many benefits, but there are upsides to not owning a home too

Full Story

DECORATING GUIDES10 Easy Fixes for That Nearly Perfect House You Want to Buy

Find out the common flaws that shouldn’t be deal-breakers — and a few that should give you pause

Full Story

LIFECreate a 'Forever House' Connection

Making beautiful memories and embracing your space can help you feel happy in your home — even if you know you'll move one day

Full Story

walt2002

rooster101Original Author

Related Professionals

Camas Landscape Architects & Landscape Designers · Carson Landscape Architects & Landscape Designers · Chattanooga Landscape Architects & Landscape Designers · Paradise Landscape Architects & Landscape Designers · Middle River Landscape Contractors · Miller Place Landscape Contractors · New Cassel Landscape Contractors · Rockwall Landscape Contractors · Smyrna Landscape Contractors · Yukon Landscape Contractors · Wilmington Window Contractors · North Hollywood Window Contractors · Oviedo Window Contractors · Pedley Window Contractors · Sebring Window Contractorsdc3mech

walt2002

rooster101Original Author

rooster101Original Author

mownie

rooster101Original Author

mownie

rooster101Original Author

rooster101Original Author

walt2002

rooster101Original Author

fish40037

rooster101Original Author

rooster101Original Author

walt2002

walt2002

walt2002

walt2002

walt2002

rooster101Original Author

rooster101Original Author

walt2002

rooster101Original Author

walt2002

rooster101Original Author

rooster101Original Author

walt2002

peppermill_32

rustyj14

dc3mech