Craftsman YTS3000 Fuse or Electrical?

lkwisc

12 years ago

Related Stories

REMODELING GUIDESHouzz Tour: Turning a ’50s Ranch Into a Craftsman Bungalow

With a new second story and remodeled rooms, this Maryland home has plenty of space for family and friends

Full Story

GREEN BUILDINGGoing Solar at Home: Solar Panel Basics

Save money on electricity and reduce your carbon footprint by installing photovoltaic panels. This guide will help you get started

Full Story

RUSTIC STYLEAt Home on the Range

Cabin retreats in idyllic locales fill the pages of the new book ‘American Rustic.’ We take you inside one of them

Full Story

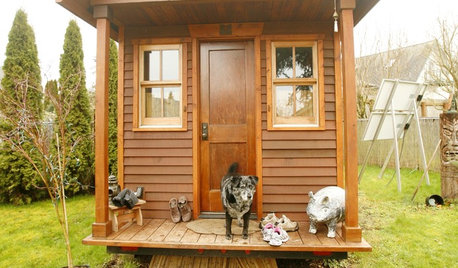

SMALL SPACESLife Lessons From 10 Years of Living in 84 Square Feet

Dee Williams was looking for a richer life. She found it by moving into a very tiny house

Full Story

HOUZZ TOURSMy Houzz: Going White and Bright in Montreal

White lacquer and wider doorways help create an airer backdrop for colorful contemporary art in a 1910 Arts and Crafts home

Full Story

HOUZZ TOURSMy Houzz: Joyful, Earth-Conscious Home in Vermont

An architect blends green construction, fine craftsmanship and profuse art in his dream home near Vermont's Lake Champlain

Full Story

MATERIALSAre You a Maker? Show Us Your Favorite Tool or Material

Houzz Call: A tool or material can be a maker’s best friend. We’d like to see your favorite — and what it helps you achieve

Full Story

REMODELING GUIDESThe Hidden Problems in Old Houses

Before snatching up an old home, get to know what you’re in for by understanding the potential horrors that lurk below the surface

Full Story

TINY HOUSESHouzz Tour: A Custom-Made Tiny House for Skiing and Hiking

Ethan Waldman quit his job, left his large house and spent $42,000 to build a 200-square-foot home that costs him $100 a month to live in

Full Story

HOUZZ TV FAVORITESMy Houzz: New Life and Style for a 1976 Airstream

The owner of this 1976 Ambassador Airstream embraces flexible furniture and clean, organized spaces

Full StorySponsored

mownie

lkwiscOriginal Author

Related Professionals

New Bedford Landscape Architects & Landscape Designers · Carson Landscape Architects & Landscape Designers · Forest Acres Landscape Architects & Landscape Designers · Mooresville Landscape Contractors · Byram Landscape Contractors · Coram Landscape Contractors · Golden Gate Landscape Contractors · Melrose Landscape Contractors · Streamwood Landscape Contractors · West Orange Landscape Contractors · Hawaiian Gardens Landscape Contractors · Brookfield Window Contractors · Granite City Window Contractors · Greenburgh Window Contractors · Tamiami Window Contractorsmownie

rwollum_yahoo_com

mownie

lkwiscOriginal Author

mownie