Craftsman 917.256611 Won't Start

LestatVIl

11 years ago

Related Stories

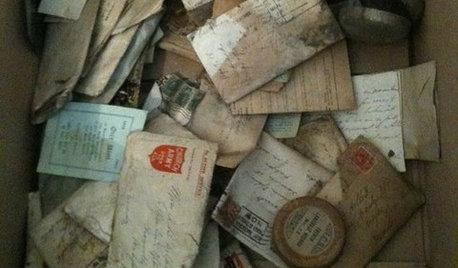

REMODELING GUIDESYou Won't Believe What These Homeowners Found in Their Walls

From the banal to the downright bizarre, these uncovered artifacts may get you wondering what may be hidden in your own home

Full Story

HOUZZ TOURSHouzz Tour: New Love and a Fresh Start in a Midcentury Ranch House

A Nashville couple, both interior designers, fall for a neglected 1960 home. Their renovation story has a happy ending

Full Story

CONTRACTOR TIPS10 Things to Discuss With Your Contractor Before Work Starts

Have a meeting a week before hammers and shovels fly to make sure everyone’s on the same page

Full Story

HOUZZ TOURSMy Houzz: It All Started With a Rug

One floor covering from Kazakhstan inspires a whole global vibe in a traveler’s San Francisco apartment

Full Story

REMODELING GUIDESWhat to Consider Before Starting Construction

Reduce building hassles by learning how to vet general contractors and compare bids

Full Story

REMODELING GUIDESHouzz Tour: Turning a ’50s Ranch Into a Craftsman Bungalow

With a new second story and remodeled rooms, this Maryland home has plenty of space for family and friends

Full Story

BATHROOM DESIGN7 Elements of Craftsman-Style Bathrooms

If you like a handmade look and simple materials, this style is tailor made for your bath

Full Story

ARCHITECTURERoots of Style: See What Defines a Craftsman Home

Charming features and intimate proportions have made Craftsman houses an American favorite. See their common details and variations

Full Story

CRAFTSMAN DESIGNCraftsman Front Doors Make an Entrance

For curb appeal, warmth and natural light, consider a classic Craftsman-style door for your home's entryway

Full Story

BEDROOMSThe Cure for Houzz Envy: Master Bedroom Touches Anyone Can Do

Make your bedroom a serene dream with easy moves that won’t give your bank account nightmares

Full Story

bill_kapaun

LestatVIlOriginal Author

Related Professionals

Windham Landscape Architects & Landscape Designers · Ashland Landscape Architects & Landscape Designers · Baltimore Landscape Architects & Landscape Designers · La Marque Landscape Architects & Landscape Designers · Lakewood Landscape Architects & Landscape Designers · Montgomeryville Landscape Architects & Landscape Designers · Hawaii Landscape Contractors · Las Vegas Landscape Contractors · Norristown Landscape Contractors · Soddy Daisy Landscape Contractors · Merrifield Landscape Contractors · Jacksonville Window Contractors · Bluffton Window Contractors · Damascus Window Contractors · Roselle Park Window Contractorsbill_kapaun

mownie

bill_kapaun

LestatVIlOriginal Author

bill_kapaun

LestatVIlOriginal Author

bill_kapaun

rustyj14

LestatVIlOriginal Author

mownie

bill_kapaun