BS 14hp drops a cylinder under load, idles great!

punishergto

13 years ago

Related Stories

SAVING WATER11 Ways to Save Water at Home

Whether you live in a drought-stricken area or just want to help preserve a precious resource, here are things you can do to use less water

Full Story

FEEL-GOOD HOMESimple Pleasures: 10 Ideas for a Buy-Less Month

Save money without feeling pinched by taking advantage of free resources and your own ingenuity

Full Story

LAUNDRY ROOMSSee an Amazing $400 Laundry Room Remodel for a Family of 8

Budget shopping and DIY spirit create folding space, smart storage and better organization for a couple and their 6 kids

Full Story

LIFEHow to Prepare for and Live With a Power Outage

When electricity loss puts food, water and heat in jeopardy, don't be in the dark about how to stay as safe and comfortable as possible

Full Story

GREAT HOME PROJECTSHow to Switch to a Tankless Water Heater

New project for a new year: Swap your conventional heater for an energy-saving model — and don’t be fooled by misinformation

Full Story

KITCHEN STORAGE13 Popular Kitchen Storage Ideas and What They Cost

Corner drawers, appliance garages, platter storage and in-counter knife slots are a few details you may not want to leave out

Full Story

MOST POPULAREasy Green: 23 Ways to Reduce Waste at Home

Pick from this plethora of earth-friendly ideas to send less to the landfill and keep more money in your pocket

Full Story

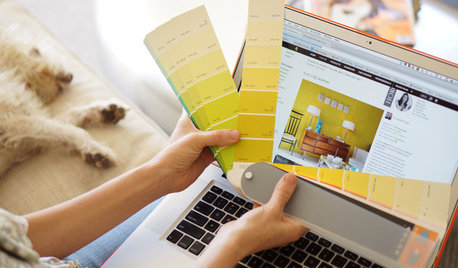

WORKING WITH PROSWorking With Pros: When You Just Need a Little Design Guidance

Save money with a design consultation for the big picture or specific details

Full Story

MOST POPULAR7 Ways to Design Your Kitchen to Help You Lose Weight

In his new book, Slim by Design, eating-behavior expert Brian Wansink shows us how to get our kitchens working better

Full Story

ARCHITECTUREThe Truth About 'Simple' Modern Details

They may look less costly and easier to create, but modern reveals, slab doors and more require an exacting hand

Full Story

punishergtoOriginal Author

baymee

Related Professionals

Allentown Landscape Architects & Landscape Designers · Newcastle Landscape Architects & Landscape Designers · Lakeland Landscape Contractors · Concord Landscape Contractors · Dickinson Landscape Contractors · East Patchogue Landscape Contractors · Englewood Landscape Contractors · Framingham Landscape Contractors · Garland Landscape Contractors · Norwalk Landscape Contractors · Palatine Landscape Contractors · San Bruno Landscape Contractors · Selden Landscape Contractors · Wichita Window Contractors · Hacienda Heights Window Contractorswalt2002

punishergtoOriginal Author

punishergtoOriginal Author

walt2002

punishergtoOriginal Author

punishergtoOriginal Author

mownie

punishergtoOriginal Author