Anyone experienced? mownie?

grass1950

11 years ago

Related Stories

LIFE10 Ways to Cope With Grief During the Holidays

If you are experiencing loss, take it from an experienced griever — life has changed forever, but it does get better

Full Story

MOST POPULAR12 Key Decorating Tips to Make Any Room Better

Get a great result even without an experienced touch by following these basic design guidelines

Full Story

MOST POPULAR9 Real Ways You Can Help After a House Fire

Suggestions from someone who lost her home to fire — and experienced the staggering generosity of community

Full Story

MODERN HOMESHouzz Tour: ’50s Ranch Redo Could Be a Keeper

An experienced house flipper puts his creative talents to work on an L.A. remodel designed for his own family

Full Story

GREEN BUILDINGEasy Green: 10 Ways Toward a Zero-Energy Home

Imagine never paying an electric bill again. With a zero-energy home, it's possible — and anyone can make it happen

Full Story

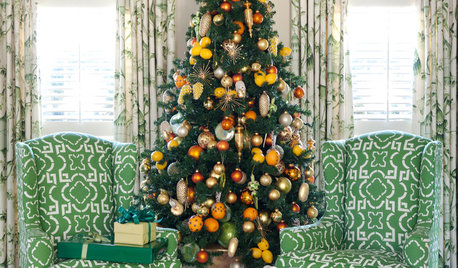

CHRISTMASReal vs. Fake: How to Choose the Right Christmas Tree

Pitting flexibility and ease against cost and the environment can leave anyone flummoxed. This Christmas tree breakdown can help

Full Story

WORKING WITH PROS6 Reasons to Hire a Home Design Professional

Doing a construction project without an architect, a designer or a design-build pro can be a missed opportunity

Full Story

LIFE10 Ways to Honor and Remember a Departed Loved One at Home

Help the grieving process and keep beautiful memories alive with these thoughtful tributes

Full Story

DECORATING GUIDES9 Ways to Create Comforting Farmhouse Style Anywhere

So you don't have 12 acres, a cow and a porch that sleeps a crowd. You can still get the warmth and coziness of a farmhouse at home

Full StorySponsored

wheely_boy

mownie

Related Professionals

Camas Landscape Architects & Landscape Designers · Elwood Landscape Architects & Landscape Designers · Milwaukee Landscape Architects & Landscape Designers · Waterbury Landscape Contractors · Dickinson Landscape Contractors · Eagle Landscape Contractors · Fort Atkinson Landscape Contractors · Fort Mill Landscape Contractors · Lemont Landscape Contractors · New Brighton Landscape Contractors · Peachtree City Landscape Contractors · Salmon Creek Landscape Contractors · Brighton Window Contractors · Estero Window Contractors · Glen Burnie Window Contractorsgrass1950Original Author

mownie

rcbe

grass1950Original Author

mownie

grass1950Original Author

rcbe

grass1950Original Author

rcbe

grass1950Original Author