Muffler replacement advice needed MTD tractor

drphi

13 years ago

Related Stories

FUN HOUZZEverything I Need to Know About Decorating I Learned from Downton Abbey

Mind your manors with these 10 decorating tips from the PBS series, returning on January 5

Full Story

PETSWhat You Need to Know Before Buying Chicks

Ordering chicks for your backyard coop? Easy. But caring for them requires planning and foresight. Here's what to do

Full Story

GREAT HOME PROJECTSHow to Give Your Driveway and Front Walk More Curb Appeal

Prevent injuries and tire damage while making a great first impression by replacing or repairing front paths

Full Story

MOST POPULARHow to Add a Backyard Shed for Storage or Living

Need a home office, a playspace or extra room for your stuff? Learn about off-the-shelf, prefab and custom sheds

Full Story

FENCES AND GATESHow to Choose the Right Fence

Get the privacy, security and animal safeguards you need with this guide to fencing options

Full Story

GARDENING AND LANDSCAPINGGrow a Lush Privacy Screen

No need to wait forever for patio privacy the green way. These 10 ideas will get your screening up and running in no time

Full Story

THE ART OF ARCHITECTUREFinding the Perfect Home for a New House

Sun, soil, water, topography and more offer important cues to siting your house on the land

Full Story

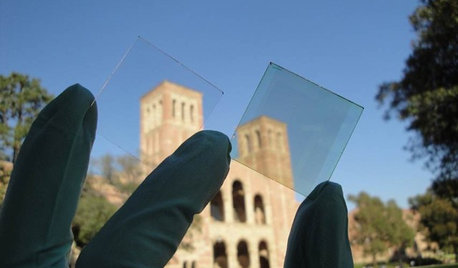

HOME TECHSmall Solar: Big Home Tech Trend in the Making

New technology enables everyday household objects to power themselves by harnessing natural light

Full Story

REMODELING GUIDESThe Case for Waiting to Remodel

We know, you're excited to make your home match your vision. But your vision may change once you've lived there awhile

Full Story

GREEN BUILDINGOff the Grid: Ready to Pull the Plug on City Power?

What to consider if you want to stop relying on public utilities — or just have a more energy-efficient home

Full Story

rustyj14

Related Professionals

Cary Landscape Architects & Landscape Designers · Garden City Landscape Architects & Landscape Designers · East Hanover Landscape Contractors · Lake Worth Landscape Contractors · North Chicago Landscape Contractors · Oakland Landscape Contractors · Seven Hills Landscape Contractors · North Aurora Landscape Contractors · Shafter Landscape Contractors · Brighton Window Contractors · Madison Window Contractors · Enumclaw Window Contractors · Hesperia Window Contractors · Surfside Window Contractors · University Window Contractors