2003 Craftsman DLT3000 battery problem

vinnie_s

11 years ago

Featured Answer

Sort by:Oldest

Comments (21)

bill_kapaun

11 years agovinnie_s

11 years agoRelated Professionals

Glendora Landscape Architects & Landscape Designers · Cornelius Landscape Contractors · Darien Landscape Contractors · Fruit Heights Landscape Contractors · Hayden Landscape Contractors · Los Banos Landscape Contractors · Middle River Landscape Contractors · Munster Landscape Contractors · North Canton Landscape Contractors · North Haven Landscape Contractors · North Plainfield Landscape Contractors · Painesville Landscape Contractors · St. Louis Landscape Contractors · Sun City Center Landscape Contractors · Palm River-Clair Mel Window Contractorsvinnie_s

11 years agobill_kapaun

11 years agovinnie_s

11 years agobill_kapaun

11 years agovinnie_s

11 years agobill_kapaun

11 years agovinnie_s

11 years agovinnie_s

11 years agobill_kapaun

11 years agorustyj14

11 years agovinnie_s

11 years agovinnie_s

11 years agobill_kapaun

11 years agovinnie_s

11 years agomownie

11 years agovinnie_s

11 years agobill_kapaun

11 years agovinnie_s

11 years ago

Related Stories

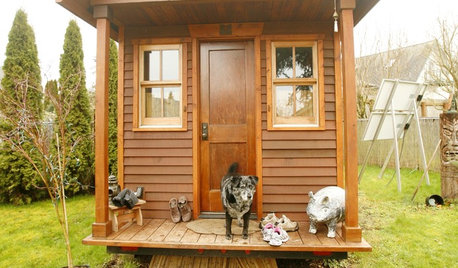

SMALL SPACESLife Lessons From 10 Years of Living in 84 Square Feet

Dee Williams was looking for a richer life. She found it by moving into a very tiny house

Full Story

KITCHEN DESIGNTrick Out Your Kitchen Backsplash for Storage and More

Free up countertop space and keep often-used items handy by making your backsplash more resourceful

Full Story

HOUSEKEEPINGHow to Wash Your House

Avoid damage to siding and plants while getting your home's exterior shining clean, with this guide to using pressure washers and hoses

Full Story

WINDOW TREATMENTSWhat’s the Right Way to Hang Roller Shades?

Over or under? It depends on how you want your shades to look, how much light you want to block and other factors

Full Story

MOST POPULARDecorating 101: How Much Is This Going to Cost Me?

Learn what you might spend on DIY decorating, plus where it’s good to splurge or scrimp

Full Story

SMALL HOMESHouzz Tour: Rolling With Simplicity in a Tiny House on Wheels

Just 240 square feet, this California home encourages efficient living — but there’s still room for yoga

Full Story

BEDROOMSThe Cure for Houzz Envy: Master Bedroom Touches Anyone Can Do

Make your bedroom a serene dream with easy moves that won’t give your bank account nightmares

Full Story

GREEN BUILDINGHouzz Tour: See a Concrete House With a $0 Energy Bill

Passive House principles and universal design elements result in a home that’ll work efficiently for the long haul

Full Story

mownie