Finding a Replacement Riding Mower Engine

ralphm

11 years ago

Related Stories

GREAT HOME PROJECTSHow to Replace Your Lawn With a Garden

New project for a new year: Lose the turfgrass for energy savings, wildlife friendliness and lower maintenance

Full Story

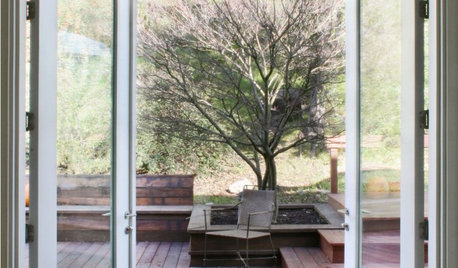

MOST POPULARFind the Right Glass Door for Your Patio

It’s more than just a patio door — it’s an architectural design element. Here’s help for finding the right one for your home and lifestyle

Full Story

THE ART OF ARCHITECTUREFinding the Perfect Home for a New House

Sun, soil, water, topography and more offer important cues to siting your house on the land

Full Story

HOUSEKEEPINGHow to Tackle Your Home To-Dos

Make quick work of minor repairs and replacements with this thorough, step-by-step approach

Full Story

LANDSCAPE DESIGNGet Along With Less Lawn — Ideas to Save Water and Effort

Ditch the mower and lower your water bill while creating a feast for the eyes with diverse plantings and gathering places

Full Story

LANDSCAPE DESIGNIs It Time to Consider Fake Grass?

With more realistic-looking options than ever, synthetic turf can be a boon. Find the benefits and an installation how-to here

Full Story

BUDGET DECORATINGPop Culture Watch: Get a Good Rap With Thrift Store Scores

Eight rooms that rock secondhand finds, in an ideabook inspired by rappers taking YouTube by storm

Full Story

TRAVEL BY DESIGNTravel Guide: Vancouver for Design Lovers

You'll find more than just great architecture in this diverse coastal Canadian city — terrific parks, shops, eateries and museums abound too

Full Story

SMALL HOMESHouzz Tour: An Illinois Loft Sparks Renovation Fever

Home improvement newbies (and newlyweds) find joy and a new income source while redoing their space themselves

Full Story

HOUZZ TV FAVORITESMy Houzz: New Life and Style for a 1976 Airstream

The owner of this 1976 Ambassador Airstream embraces flexible furniture and clean, organized spaces

Full StorySponsored

Columbus Area's Luxury Design Build Firm | 17x Best of Houzz Winner!

mownie

ralphmOriginal Author

Related Professionals

Montgomeryville Landscape Architects & Landscape Designers · Brookside Landscape Contractors · Aloha Landscape Contractors · Brookline Landscape Contractors · Choctaw Landscape Contractors · El Sobrante Landscape Contractors · Ellicott City Landscape Contractors · Fort Payne Landscape Contractors · Hawthorne Landscape Contractors · La Verne Landscape Contractors · Plantation Landscape Contractors · The Villages Landscape Contractors · Vineyard Landscape Contractors · West Chester Landscape Contractors · Kingsburg Landscape Contractorsbill_kapaun

rustyj14

ralphmOriginal Author

rustyj14

ralphmOriginal Author

txtom50

rustyj14

Paul171

rustyj14

bill_kapaun

dr_mike

ssparay