Need to Rebuild Craftsman LT-1000 Mower Deck

harleysilo

10 years ago

Related Stories

GARDENING AND LANDSCAPINGChoosing a Deck: Plastic or Wood?

Get the pros and cons of wood, plastic, composite and more decking materials, plus a basic price comparison

Full Story

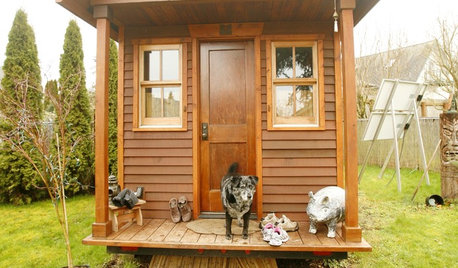

SMALL SPACESLife Lessons From 10 Years of Living in 84 Square Feet

Dee Williams was looking for a richer life. She found it by moving into a very tiny house

Full Story

FARMHOUSESHouzz Tour: German Tradition Deep in the Heart of Texas

Rooted in architecture from the 1800s, this award-winning home mixes history with the vernacular of today

Full Story

ECLECTIC HOMESMy Houzz: A Treehouse-Like Dwelling in Los Angeles

Fragrant breezes, chirping birds and glorious sunsets provide a beautiful live-work setting for this design couple and their kids

Full Story

HOUZZ TOURSMy Houzz: Creative Thrifting Beautifies a Texas Bungalow

Secondhand finds and a designer’s gift for reinvention turn a historic-district house into a quirkily elegant family home

Full Story

GARAGESKey Measurements for the Perfect Garage

Get the dimensions that will let you fit one or more cars in your garage, plus storage and other needs

Full Story

MOST POPULARHow to Add a Backyard Shed for Storage or Living

Need a home office, a playspace or extra room for your stuff? Learn about off-the-shelf, prefab and custom sheds

Full Story

MOVINGHouse Hunting: Find Your Just-Right Size Home

Learn the reasons to go bigger or smaller and how to decide how much space you’ll really need in your next home

Full Story

GARDENING AND LANDSCAPING10 Ways to Open a Kitchen to the Outdoors

Have your cooking and your nice weather too, with a kitchen setup that embraces indoor-outdoor flow

Full StorySponsored

mownie

harleysiloOriginal Author

Related Professionals

Windham Landscape Architects & Landscape Designers · Aberdeen Landscape Contractors · Cordele Landscape Contractors · Corona Landscape Contractors · Dunwoody Landscape Contractors · Golden Landscape Contractors · Methuen Landscape Contractors · Muttontown Landscape Contractors · Natick Landscape Contractors · Rockville Landscape Contractors · Stallings Landscape Contractors · Twin Falls Landscape Contractors · Hawaiian Gardens Landscape Contractors · Sayville Window Contractors · Winnetka Window Contractorsbill_kapaun

mownie

harleysiloOriginal Author

harleysiloOriginal Author

harleysiloOriginal Author

harleysiloOriginal Author

mownie

harleysiloOriginal Author

snorkel12068

snorkel12068

harleysiloOriginal Author

mownie

harleysiloOriginal Author